The 100 series control valve design features

Innovative packing structure design

The top guided structure design

Detachable structure design

Standard modular design

Reading tips

For detailed product information, product animation, please click "contact us",

Then visit the company's website, Download and reading Or contact us directly

Outline

The 10P Series single-seat control valve adopts the top guided unbalanced structure, featured by high strength, heavy load, S type flow channel, low pressure drop loss, high flow coefficient wide adjustable range, high flow characteristic precision, etc. This kind of control valve is suitable for applications with relatively low differential pressure with tight shut-off. It is suitable for controlling medium flow or pressure. The cage adopts the press-in type seat design, which solves the problems of difficult disassembly and high leakage of the traditiona l thread screw-in type seat and prolongs the service life. The flow to open design is adopted, and the medium flow direction tends to the opening direction of the valve with good controllability of small opening and low flow characteristic distortion. Special cages with noise reduction and anti- cavitation functions can be offered according to the requirements in different service conditions.

Flow characteristic

The flow characteristic of the control valve is the relationship between the flow of the incompressible fluid that passes through the control valve and the opening of the control valve when the differential pressure at the two ends of the valve is invariable. This flow characteristic is called inherent flow characteristic.

Linear flow characteristic

It indicates that the flow and opening of the control valve are in t he linear relationship. It is usually used for applications w ith small change of differential pressure, which is almost invariable. When the pressure drop on the valve becomes the main pressure drop in the system, the linear flow characteristic is often used.

Equal percentage flow characteristic:

It indicates the flow change rate caused due to the change of travel is in direct proportion to the original flow at the point. It is usually used in applications that require relatively wide adjusting range, or w hen the system pressure loss is much higher than that of the valve, or when the opening change and differential pressure change on the valve is relatively high.

Quick open

It is mainly used for on-off control system. It is required that the flow should be high when the

Opening is small, and with the increase of the opening, the flow w ill reach the highest value very soon. After that, if the opening increases again, the change of flow is very title.

|

DN |

15~450mm |

|

PN |

Class150~2500 |

|

Applicable temperature range |

-196- 570 |

|

Trim features |

Top guided, unbalanced trim, quick disassembly cage structure |

|

Body type |

straight-through type, angle type. |

|

Bonnet type |

standard type, heat dissipation type, cryogenic type, bellows |

|

Flow characteristic |

equal percentage, linear, quick open |

|

Shut-off class |

ASME B16.104 V (standard metal seat) |

|

ASME B16.104 V I (shut-off soft seat) |

|

Pipe connection type |

flange type, butt welding type |

|

Actuator type |

pneumatic diaphragm actuator |

|

pneumatic piston actuator |

|

Electric actuator |

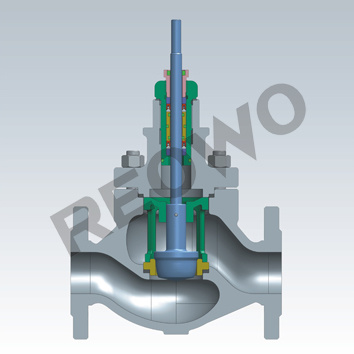

Exploded view of 10P Series

Bonnet type

1 Standard bonnet

The standard bonnet is normal temperature upper bonnet. The bonnet material is the same as that of the body, playing the function of sealing the body and linking the actuator. Working temperature: -30- 230

2 High temperature bonnet

The high temperature bonnet is specially designed for high temperature service conditions. The heat sink enhances the contact area between the bonnet and the surrounding air so as to play the

function of heat dissipation. It can effectively protect the packing and actuator.

Working temperature: +230~ 530 or -45~ -5

3 Cryogenic extended bonnet

The cryogenic extended bonnet is suitable for media under low temperature status (such as liquid oxygen, liquid nitrogen). This kind of upper bonnet can effectively protect the packing and actuator. The standard material adopted is 304 or 316. Materials of different expansion coefficients can also be adopted according to different service conditions Working temperature: -196- 45

4 Metal bellows seal bonnet

The metal bellows seal bonnet is installed with the stainless steel bellows assembly to isolate the media from the outside and ensure the stem will make upward and downward movement. In addition, the upper bonnet is also provided with the standard packing box to ensure the media will not leak and cause waste or produce pollution to the environment. Working temperature: -60- 530

Materials for main parts

|

Part name |

Material |

|

Body \bonnet |

WCB\WC6\WC9\CF8\CF8M \CF3\CF3M |

|

Plug, seat |

304\316\316L\410\420\17-4PH\Monel, Hastelloy |

|

Cage |

CF8\CF8M |

|

Stem |

304\316\316L\420\17-4PH |

Note: Special materials can be offered according to customer requirements.

Packing structure

As a seal at the stem, the packing plays the sealing function for the upward and downward movement at the stem. The traditional solution is the pressing board type packing box structure. Although this structure can play the sealing function, the problem that high friction at the stem will cause big dead band, no response and small signal still exists. To solve the above

problem, the 100 Series control valve is designed with the new type packing box structure based on the principle of ensuring effective sealing at the stem, improving the structure and reducing stem friction. The structure has such features as: The integral packing box is easy to replace and repair. Many U type seal rings with sealing compensation function replace the traditional PTFE

V type packing.

Standard packing box structure

The integral packing box is the standard packing structure. It is easy to replace and repair with the modular design.

Working temperature: -30 - 260

The packing is composed of many U type seal rings with sealing compensation unction.

High temperature packing box structure

The V type flexible graphite serves as the high temperature packing.

Working temperature: -45 - 530

The high temperature packing is composed of three V type graphites of different tapers.

Bellows packing box structure

The bellows stem sealing structure often adopts the bellows. The standard packing box with dual sealing will absolutely seal toxic and cryogenic media.

Working temperature: -60 - 530

The metal bellows isolates the media fromthe outside, and ensures the stem makes upward and downward movement.

Working pressure and temperature range of sealing materials

|

Type |

Material |

temperature range |

|

standard |

PPL |

-30- 260 |

|

PTFE |

-30- 230 |

|

high temperature |

V type flexible graphite |

-30- 540 |

|

PTFE |

-50- 250 |

|

bellows seal |

304/316 |

-196- 400 |

|

Hastelloy C/ MO ENEL |

-250- 530 |

Gasket

The 100 Series is a new generation high performance control valve. It adopts self aligning insertion type thread less seat, which is fixed axially by the bonnet and cage. Metal-to-metal contact between the bonnet and body and between the seat and body is realized. The gap between them is filled by the packing gasket and sealing is realized. The compression degree of the bonnet sealing gasket is determined by the bolt pre-tightening force on the bonnet. Only after the concentricity between the bonnet and body is ensured, will it be ensured that the plug and seat are vertically aligned so as to meet the strict sealing requirement. When the bonnet is completely installed, its force is transferred to the seat through the cage or sleeve. Only when the height tolerance of seat, cage or sleeve is very close, will the sealing gasket of the seat achieve proper compression, so that sealing is ensured and no leakage is caused due to over pressure on the sealing gasket of the seat . If the valve is correctly assembled, the self aligning seat with the top guided structure will fit well with the plug without the need of grinding.

Various gasket materials and working temperature range

|

Type |

Material |

Temperature range |

|

Flat gasket(for general purpose) |

PTFE |

-130~150 |

Serrated gasket

(for high temperature and high pressure) |

304/316 |

-196~500 |

Spiral wound gasket

(for high temperature and corrosion) |

304/316+flexible graphite |

-196~500 |

The sealing gaskets made of special materials can be used under higher temperature.

Seal ring solutions in the balanced trim

The balanced seal ring is mainly used in the balanced trim to play the sealing function. It is a core technological part in the sleeve type control valve. T he balanced trim type control valve produced by our company provides three kinds of seal rings for users.

Introduction to the balanced seal ring

@The spring actuated PTFE seal is ahigh performance seal that is assembled w ith special spring in the UPTFE.

@The proper spring force and the fluid pressure in the system will eject the seal lip and slightly press the sealed face so as to achieve excellent sealing effect.

@The seal lip is short and thick, which is the best feature, so as to reduce friction and prolong the service life.

Features of the balanced seal ring

@Used for reciprocating and rotating movements.

@Suitable for most fluids and chemical products

@Low friction coefficient

@Without the occurrence of crawling during precision control, the dead band of the valve is reduced.

@Good anti-wear performance and size stability

@Adapting to sharp temperature change

@No pollution

Selection of sealing materials

|

Seal ring type |

Material |

Working temperature |

|

Balanced seal ring |

PPL |

-30~260 |

|

Graphite seal ring |

Flexible graphite |

-196~500 |

|

Metal seal ring |

INCONEL 718 |

-196~560 |

Zhejiang Jinfeng Automatic Meter Co., Ltd. Was established in 2003, specialized in designing and manufacturing control valves for more than 10 years, provided high quality solutions and products in such industries as petroleum, chemical industry, electric power, metallurgy for process control systems. www.reowo.com