Quick Details

Type:

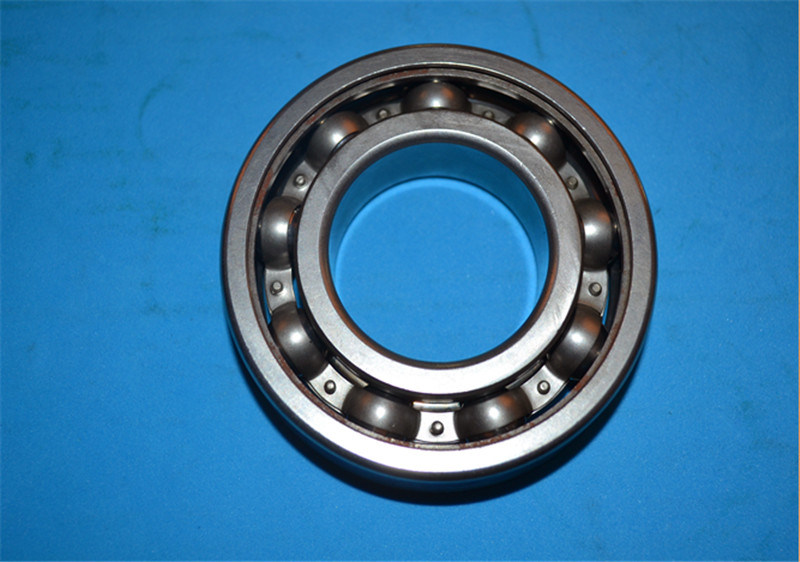

Ceramic Ball, Hybrid Ceramic Ball Bearing

Brand Name: ZX Bearings

Bore Size: 2 - 100 mm

Outside Diameter: 5 - 200 mm

Model Number: Ceramic Hybrid Bearing

Place of Origin: Shanghai China (Mainland)

Structure: General, flanged, extended inner ring

Vibration level codes: V4, V3, V2, V1

Application:

Medical devices, semiconductors, machine tools, turbine flow meters

Internal clearance codes: C0, C2, C3, C4, C5

Material: Ceramic

Retainer: PTFE, Nylon, PEEK

Lubrication: Oil, grease, dry

Noise Level: Z1, Z2, Z3, Z4

Package: Tube

Ceramic bearing

1. Wearable.

2. Resistance to Corrosion etc.

Features: 1. High speed bearings: 12000rpm--75000rpm 2. High temperature-resistant bearing: 100° C--800° C. It can been applied in kiln, plastic, steel and other equipments that can bear high temperature 3. Corrosion-resistant bearings 4. Electric-insulated bearings 5. Vacuum bearings: Self-lubricating without oil

Silicon Nitride(Si3N4) full ceramic ball bearing

1. Full ceramic bearing made with ZrO2 have excellent performance as special electrical and magnetism, wear and corrsion resistance, lubrication and maintance free when working, especiall high and low-temperature application, etc., could be used in awful environment and specially condition,

2. The rings and balls: Full ceramic materia: ZrO2

3. The cage: PTFE, GFRPA66-25, PEEK, Phonemic Textiles Tube, etc.

Features of hybrid ceramic ball bearing:

- Full ceramic bearing, SI3N4 or ZRO2 races and balls, PTFE cage or full balls no cage.

- Hybrid ceramic bearing, chrome/ stainless steel rings, SI3N4/ZRO2 balls, nylon/Peek cage.

Application of ceramic bearing:

- Ceramic bearing has the characteristics of high temperature resistance, cold resistance, abrasion resistance, corrosion resistance and insulation, and can be used in extremely bad environment and special conditions.

- Ceramic bearing can be widely used in aviation, spaceflight, navigation, petroleum, chemical industry, automobile, electronics, metallurgical, power, textile, pumps, medical equipment and scientific research.

Hybrid Ceramic Ball Bearing

We supply the Hybrid Ceramic Bearing. Full Complement ceramic bearings, Ceramic Balls at high precision and competitive price.

High speed ceramic ball bearings

Models:

672~6709

682~6820

692~6920

602~6020

623~6220

633~6320

16000

MR52-MR149, R, FR, MR, MFR

Features:

1. High speed bearings: 12000rpm--75000rpm

2. High temperature-resistant bearing: 100° C--800° C. It can been applied in kiln, plastic, steel and other equipments that can bear high temperature

3. Corrosion-resistant bearings

4. Electric-insulated bearings

5. Vacuum bearings: Self-lubricating without oil

|

Hybrid Ceramic Ball Bearing |

|

Hybrid Bearing - are an excellent choice for many reasons. They perform well in many applications because they have the following qualities: low density, strong solidity, low friction coefficient, abrasion resistance, magnetic resistance, acid and alkali resistance, good resistance to wear and tear, electric insulation, self-lubrication, temperature resistance of over 300C, high speed rolling rates, cool temperatures, light weight (60% lighter than steel), elasticity (50% higher than steel), and a long service life (3 to 5 times longer than full chrome steel bearings). Features: |

|

Brand |

XZ Bearings |

|

Name |

Hybrid Ceramic Ball Bearing |

|

Model |

60 series, 62 series, 63 series, 67 series, 68 series and 69 series.. |

|

Material |

Ceramic |

Certificate |

ISO9001:2001 |

|

Precision |

P0, P6, P5, P4 |

|

Bore Size |

2mm-100mm |

Outside diameter |

5mm-200mm |

|

Clearance |

C0,C1,C2,C3,C4,C5 etc. |

|

Cage Type |

PTFE, Nylon, PEEK |

|

Seals Type |

ZZ,RS, 2RS, R2, Z, 2Z, 2RZ etc |

|

Features |

low density, strong solidity, low friction coefficient, abrasion resistance, magnetic resistance, acid and alkali resistance, good resistance to wear and tear, electric insulation, self-lubrication, temperature resistance of over 300C, high speed rolling rates, cool temperatures, light weight (60% lighter than steel), elasticity (50% higher than steel), and a long service life (3 to 5 times longer than full chrome steel bearings). |

|

Application |

Electro plating, electro polishing ,Food processing, vacuum applications.Fiber processing, conveyor processing. Medical radiation, photo processing,Computer assembly, electronics applications, Medicine equipment, wet applications. |

|

Package |

pallet, wooden case,industrial package or as customers' requirement |

|

Price |

FOB, CFR, CIF |

Delivery Time |

5-10 days |

|

Flange |

Open |

Shield |

Boundary Diameter |

|

d |

D |

Df |

|

F |

681 |

|

1 |

3 |

3.8 |

|

F |

691 |

|

1 |

4 |

5 |

|

F |

682 |

ZZ |

2 |

5 |

6.1 |

|

F |

602 |

ZZ |

2 |

7 |

8.5 |

|

F |

603 |

ZZ |

3 |

9 |

10.5 |

|

F |

623 |

ZZ |

3 |

10 |

11.5 |

|

F |

684 |

ZZ |

4 |

9 |

10.3 |

|

F |

685 |

ZZ |

5 |

11 |

12.5 |

|

F |

605 |

ZZ |

5 |

14 |

16 |

|

F |

606 |

ZZ |

6 |

17 |

19 |

|

F |

626 |

ZZ |

6 |

19 |

22 |

|

F |

607 |

ZZ |

7 |

19 |

22 |

|

F |

688 |

ZZ |

8 |

16 |

18 |

|

F |

608 |

ZZ |

8 |

22 |

25 |

|

Bearing No |

Bore d(mm) |

O.d D(mm) |

Width B(mm) |

Load Rating |

Weight (kg) |

|

Dynamic |

Static |

|

695 |

5 |

13 |

4 |

0.83 |

0.39 |

0.0022 |

|

696 |

6 |

15 |

5 |

1.13 |

0.56 |

0.0039 |

|

697 |

7 |

17 |

5 |

1.55 |

0.78 |

0.0053 |

|

698 |

8 |

19 |

6 |

2.03 |

1.05 |

0.0072 |

|

699 |

9 |

20 |

6 |

1.9 |

0.99 |

0.0075 |

|

6900 |

10 |

22 |

6 |

2.07 |

1.12 |

0.01 |

|

6901 |

12 |

24 |

6 |

2.2 |

1.24 |

0.011 |

|

6902 |

15 |

28 |

7 |

2.64 |

1.51 |

0.017 |

|

6903 |

17 |

30 |

7 |

2.79 |

1.66 |

0.018 |

|

6904 |

20 |

37 |

9 |

5.05 |

3.08 |

0.036 |

|

6905 |

25 |

42 |

9 |

5.63 |

3.68 |

0.042 |

|

6906 |

30 |

47 |

9 |

5.82 |

3.97 |

0.048 |

|

6907 |

35 |

55 |

10 |

9.5 |

6.8 |

0.074 |

|

6908 |

40 |

62 |

12 |

13.7 |

9.9 |

0.11 |

|

6909 |

45 |

68 |

12 |

14.1 |

10.9 |

0.132 |

|

6910 |

50 |

72 |

12 |

14.5 |

11.7 |

0.133 |

|

|

ID |

OD |

Width |

chamfer |

LOADING(KN) |

BALL |

WEIGHT |

|

Dynamic |

Static |

No. |

Size |

KG |

|

Cr |

Cor |

mm |

|

6000 |

10 |

26 |

8 |

0.3 |

4.55 |

1.95 |

7 |

4.763 |

0.019 |

|

6001 |

12 |

28 |

8 |

0.3 |

5.1 |

2.39 |

8 |

4.763 |

0.021 |

|

6002 |

15 |

32 |

9 |

0.3 |

5.6 |

2.84 |

9 |

4.763 |

0.035 |

|

6003 |

17 |

35 |

10 |

0.3 |

6.8 |

3.35 |

10 |

4.763 |

0.04 |

|

6004 |

20 |

42 |

12 |

0.6 |

9.4 |

5.05 |

9 |

6.35 |

0.068 |

|

6005 |

25 |

47 |

12 |

0.6 |

10.1 |

5.85 |

10 |

6.35 |

0.079 |

|

6006 |

30 |

55 |

13 |

1 |

13.2 |

8.3 |

11 |

7.144 |

0.113 |

|

6007 |

35 |

62 |

14 |

1 |

16 |

10.3 |

11 |

7.938 |

0.149 |

|

6008 |

40 |

68 |

15 |

1 |

16.8 |

11.5 |

12 |

7.938 |

0.185 |

|

6009 |

45 |

75 |

16 |

1 |

21 |

15.1 |

12 |

8.731 |

0.231 |

|

6010 |

50 |

80 |

16 |

1.1 |

21.8 |

16.6 |

13 |

8.731 |

0.256 |

|

6200 |

10 |

30 |

9 |

0.6 |

5.1 |

2.39 |

8 |

4.763 |

0.032 |

|

6201 |

12 |

32 |

10 |

0.6 |

6.1 |

2.75 |

7 |

5.953 |

0.037 |

|

6202 |

15 |

35 |

11 |

0.6 |

7.75 |

3.6 |

8 |

5.953 |

0.045 |

|

6203 |

17 |

40 |

12 |

0.6 |

9.6 |

4.6 |

8 |

6.747 |

0.066 |

|

6204 |

20 |

47 |

14 |

1 |

12.8 |

6.65 |

8 |

7.938 |

0.106 |

|

6205 |

25 |

52 |

15 |

1 |

14 |

7.85 |

9 |

7.938 |

0.128 |

|

6206 |

30 |

62 |

16 |

1 |

19.5 |

11.3 |

9 |

9.525 |

0.199 |

|

6207 |

35 |

72 |

17 |

1.1 |

25.7 |

15.3 |

9 |

11.112 |

0.288 |

|

6208 |

40 |

80 |

18 |

1.1 |

29.1 |

17.8 |

9 |

12 |

0.366 |

|

6209 |

45 |

85 |

19 |

1.1 |

32.5 |

20.4 |

10 |

12 |

0.398 |

|

6210 |

50 |

90 |

20 |

1.1 |

35 |

23.2 |

10 |

12.7 |

0.454 |

|

6300 |

10 |

35 |

11 |

0.6 |

8.2 |

3.5 |

6 |

7.144 |

0.053 |

|

6301 |

12 |

37 |

12 |

1 |

9.7 |

4.2 |

6 |

7.938 |

0.06 |

|

6302 |

15 |

42 |

13 |

1 |

11.4 |

5.45 |

7 |

7.938 |

0.082 |

|

6303 |

17 |

47 |

14 |

1 |

13.5 |

6.55 |

7 |

8.731 |

0.115 |

|

6304 |

20 |

52 |

15 |

1.1 |

15.9 |

7.9 |

7 |

9.525 |

0.144 |

|

6305 |

25 |

62 |

17 |

1.1 |

21.2 |

10.9 |

7 |

11.5 |

0.232 |

|

6306 |

30 |

72 |

19 |

1.1 |

26.7 |

15 |

8 |

12 |

0.36 |

|

6307 |

35 |

80 |

21 |

1.5 |

33.5 |

19.1 |

8 |

13.494 |

0.457 |

|

6308 |

40 |

90 |

23 |

1.5 |

40.5 |

24 |

8 |

15.081 |

0.63 |

|

6309 |

45 |

100 |

25 |

1.5 |

53 |

32 |

8 |

17.462 |

0.814 |

|

6310 |

50 |

110 |

27 |

2 |

62 |

38.5 |

8 |

19.05

|

XZB is one of the leading providers of China's Bearing Industry and a long-time partner of professional dealers.

XZB is one of the Custom Bearing Manufacturers and world wide Distributors of all types of Bearings, specializing in Ceramic balls, Bearings (Inch & Metric Sizes) made from Ceramic (Si3N4/ZrO2), Stainless (440c/316) or Chrome Steel(SAE52100 steel); Tolerance ABEC1, 3, 5, 7. Level.

We work directly with our OEMs and Bearing Distributors. Our engineers can help you with bearing, shaft and housing tolerances as well as semiconductor applications, cryogenic applications, extreme hostile environments, and extreme delta T temperatures environments.

We also stock other manufacturer's bearings. We distribute bearings for extreme high temperature. We can help to design/manufacture any bearing within a 2-week turnaround.

We are specialized in all kind of full ceramic balls, (eg: Si3N4, ZrO2, Al2O3, SIC balls for bearing and other purpose) as well as Full Ceramic Bearing, Hybrid ceramic Bearing, Stainless Ball Bearing. Thin section Ball bearings. ) Besides, we are working together with over 50 factories in bearing fields.

We are uniquely positioned to provide OEM's and Distributors a full range of engineered solutions in addition to stocking thousands of bearing and bearing related products to cost-efficiently and consistently provide just-in-time delivery.

Our quality is ranked #1 by bearing distributors and OEM's. Our Physical Coated rings, Ceramic Balls and Moly/PTFE retainers give you the longest lasting best performing bearings in the industry.

Allow us the opportunity to use our expertise to solve your toughest bearing applications.

Please consider us 1st for your bearing needs as well as all custom bearing requirements.