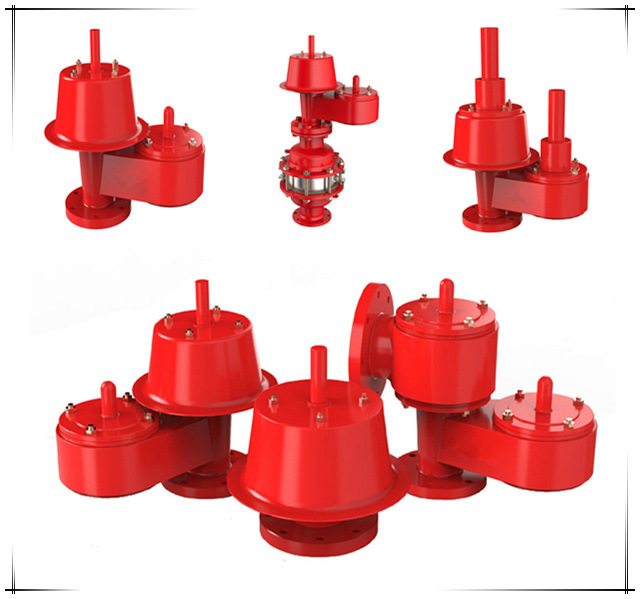

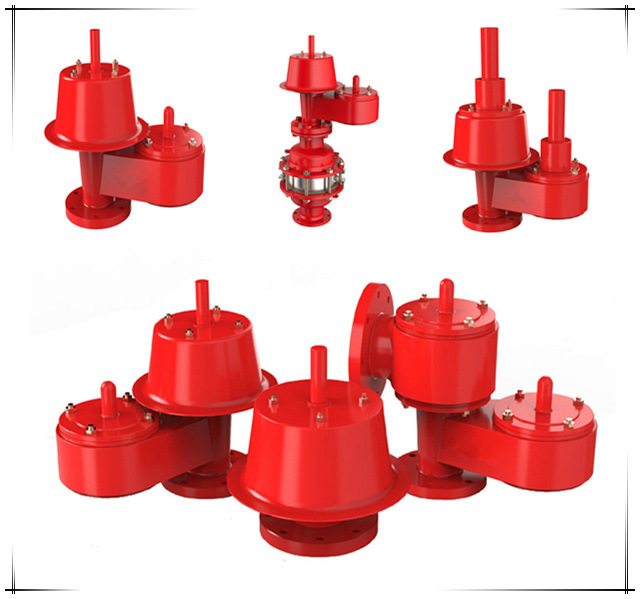

All-weather fire proof &explosion-proof breathing valve

Breathing valve is a kind of air breather which install on the petrochemical fixed storage tank, in order to avoid tank over the pressure or vacuum making the storage tank destruct, prevent the outside flame enter, reduce the tank fluid volatile.

Explosion-proof fire breathing valve is to maintain the tank pressure balance, reduce safety energy-saving products medium volatile, but also the use of principles of vapor heat transfer, protect the respiratory valve parts is not easy to freeze, the breathing valve to ensure the normal work, equipped with fire retardant explosion-proof function.

Fire breathing valve produced by our company has simplified structure, ventilation volume, less leakage, corrosion resistance, insulation, etc.

The valve adopts polytetrafluoroethylene material, has the advantages of low temperature resistant, anti frost.

The electrostaticprotection device is provided with a respiratory valve, the valve and the tank to keep the same potential moment.

Operating pressure:

Type A: +355pa(+36mmH2O) -295pa(-30mmH2O)

Type A: +355pa (+36mmH2O) -295pa (-30mmH2O)

Type B: +980pa(+100mmH2O) -295pa(-30mmH2O)

Type B: +980pa (+100mmH2O) -295pa (-30mmH2O)

Type C: +1950pa(+200mmH2O) -295pa(-30mmH2O)

Type C: +1950pa (+200mmH2O) -295pa (-30mmH2O)

Type D: according to user requirement (special pressure rating)

Note:

under normal circumstances, (fire) breathing valve operating pressure to B shall prevail;

Applicable materials:

gasoline, kerosene, diesel, aromatics, sulfur, air and other petrochemical materials;

Environment temperature:

-40 ºC -+60 ºC;

Shell material:

HT, AL, A3, 18-8, 304, 304L, 316, 316L.

Flange standards:

HG20592-97 PN1.0 (also can be produced according to user specified criteria)

PRODUCTS

WORKSHOP

INSPECTION

We welcome all the world customers to contact us for more cooperation.

With our years of technical knowledge and experience,we assure you,

Naibang will be one of your best parters in China.

Any interest,please do not hesitate to contact us.

| Specifications |

| Applicable Standards |

|

| Design | ASME B16.34, API6D |

| Fire safe | API 607 |

| Anti static | API 608, API6D |

| Face to face | ASME B16.10, API6D |

| Welding ends | ASME B16.25 |

| Inspection and test | API 598, API 6D |

Zhejiang NaiBang Valve Co., Ltd. is a specialized company devoted into manufacture and sales of valves, the company situates in ou-bei town-the center of China's pumps & valves, with ground area 18800m2, machine workshop, assemble workshop and synthetic finished half - finished warehouse. The company possesses 210 precise equipments, the advanced numeral control machines ensure the flexibility and exchangeability of all the product parts. The company flourishes year by year, and its products have been widely used in lines of domestic large PowerStation configuration, dirty water processing, urban construction, petroleum-chemical, oil extraction, metallurgy, chemical fertilizer, paper production and pharmacy, exported to many countries and regions, gains the users' unanimous praise and confidence.

The company has a modernized staffs of tech research and product development, ISO9001 certificated. And now the company has the capability of manufacturing big series of high temperature and hi-gh pressure power station gate valve, ball valve, globe valve, check valve, butterfly valve, with the strength of API valve, Wafer check valve and forged valve, and the wafer check valve mainly cover wafer single disc lift and swing check valves and wafer double disc swing check valves (H77, H76, H74, H72, H71, H46 and H44). Diameter of valves varies from DN15 to DN2000(1/2'-72' ), working pressure varies from PN1.6MPa to 42 MPa(150lb to 2500lb), and working temperature from -196 Celsius degree to +570 Celsius degree; The main body adopts WCB, WC6, WC9, Cr5Mo, 20Crmo, 12Crmov, 15Crmov, CF3m, CF8m. The company possesses full precise casting equipments, integrated physical and chemical gauges, experimentation equipments and test methods, as well CAD design capability, which ensure products always in high quality.