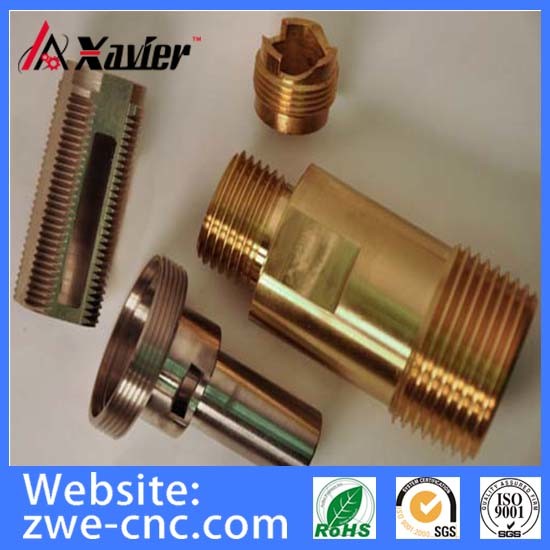

Brass CNC Lathe turning Parts for Valve

Xavier specilized in Customized as per

customer's 2D/3D drawing or samples.

Sending drawing,others to Xavier.

| Description | Brass CNC Lathe turning Parts |

| The Process | CNC turning |

All

Production Process | 1.Drawing Checking by Engineering ,

2.Terminal confirm by customer ,

3.Material Purchasing(SGS testing),

4.Arrange Production (Parts will be measure every two hours) ,

5.Updates production for customer every two or three days

6.Part size full check(Machining finished)

7.Surface finished

8.Part size full check again(after surface finish)

9.Sent customer pictures and QC report

10.Package (after customer confirmation)

11.Arrange shipping

(DHL,UPS ,Fedex,TNT or by sea by air mass cargo shipping)

12.After sale Tracking

(Ensure every parts you received will 100% Exactly) |

Material

| Brass Series |

| Tolerance | +/-0.01mm |

| Lead time | For sample 5-15days,

for mass production depend on the quantity. |

| Material advantage | High strength, hardness, resistance to chemical corrosion |

| QC system | 100% inspection before shipment |

| Packing | Poly bag,Carton,Solid Wooden Box,

as per customer's requirement |

| Trade terms | EXW,FOB,CIF,CFR,as per customer's request |

| Payment terms | L/C,T/T,Paypal,Money Gram or Western Union is acceptable. |

| Shipment terms | By sea,by air,by express(DHL.FEDEX.UPS,TNT) is ok. |

Business scope

Aviation parts,

Marine Parts,

Military parts

| ,Auto parts,

Carbon Fibre parts,

Mechanical parts

|

| Detailed as Below |

| 1.Aluminum Precision Product | 2.Extrusion/ Profile |

| 3.Hardware | 4.Injection molding |

| 5.Aluminum Frame | 6.Furniture Part |

| 7.Aluminum Office and Living Product | 8.CNC Precision Milling Part |

| 9.CNC Precision Turning Part | 10.Punch& Stamping& Stretching& Riveting& Assembly |

| 11.Die Casting& Welding& Forging& Bending Part | 12.Medical Aluminum Part |

| 13.Aluminum Pipe | 14.Large Cross-section/

High Challenge Heat Sink |

| 15.Mechanical Industrial product/ Auto Part | 16.LED Aluminum Accessory |

| 17.Mold Design and Manufacture | 18.Surface treatment |

Xavier Precision :

Materials: carbon fiber,stainless steel, copper, brass, carbon steel,

aluminum (according to customers' requirement)

Surface treatment: Zn-plating, Ni-plating, Cr-plating, tin-plating, copper-plating,

the wreath oxygen resin spraying, the heat-disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing and more

Applications: automotive, instruments, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment,

light industry products, sanitation machinery, market/hotel equipment supplies,

art ware and more

Packaging: inner plastic bag, outer carton box,

and we can also pack products according to your requirements

Our features: A company with industry and trade integration

Workforce: A group of experienced production technician,

sophisticated engineer and dedicated QC

About us:

Our company specializing in the production of CNC/auto lathe,

shafts, screws, stamping parts and other metal parts

Our main production modes are designing and

proofing based on customers' drawings or samples

QC:

Firstly, check the raw material before massive production;

During production, technicians self-check and Engineer

spot check to assure the good quality.

QC inspect after products finished

Before package, we will choose the best way

to avoid damages during transportation.

Salesmen who were trained the technical know-how

spot check before shipping

Exporting to Europe, Asia, Middle East,North America, over 20 countries and regions

Developing more fashionable and pratical new models for global customers.

Product Features:

1) skillful manufacture

2) modern design

3) corrosive and age resistance

4) color customized

5) high intensity

6) excellent dimension stability

Xavier Precision Co., Ltd. is located in Shenzhen, China. Over this years mainly to provide military industry, aerospace OEM metal parts for AVIC, 713 Institute, 628 Institute, 132 manufacturer and so on. During Cooperation we get much more produce experience, and research many new parts, improve our technology, especially in the special materials, new materials, aerospace aluminum and so on.

In 2013 years Xavier registered in Hong Kong and began to explore the international market. Mainly Provide metal cutting, sheet metal / welding, casting, forging, stamping and other services, for the global military, aerospace, automotive, medical, machinery, design and production of precision components, complex non-standard parts.

2014 Xavier signed an cooperation agreement with Germany and Belgium 2 design company. Whose Designers both have more than 15 years of professional experience. Mainly supply design structure, cost analysis, assembly and testing, technical support and after-sales service for European and North-American customer, To build a low-cost, high-quality system, achieve win and win.

On the produce processing, Xavier have very experienced technology engineer whose more than 25 years experience in military factories mechanical for product analysis process. Combined with ISO9001 quality management system:

Each part base on the material, quantity, performance parameters

Required to improve the production process;

Each production process strictly according the SOP document;

Writing CAM toolpath automatically performed every cutting process;

Each CNC machines are equipped with an automatic tool changer system;

Each batch of products are own inspection reports, any problem can be traced back production, equipment, IPQC, FQC and all other relevant details, Achieve improvement and upgrading speed and accurate for service and quality.

Simulation processing --equipment testing → First processing inspection → → Recording the machining size rules → Recording the cutter compensation rules → Recording cutter life-Recording random inspection---check the standard of processing --Finished products.

The whole processing which can avoding the unsteady -tolerance, scratches and other defects caseued by

Worker touch this parts.

Use High-precision Tech!

Building world-wide brand!

High, precison, accurate is Xaviers key values,

CNC machining one-stop service is Xaviers aim.

Customer satisfy is Xavier pursuit!