Yoke Sleeve

The standard material of the Yoke Sleeve is Nodular Ni-resist D2 with over a 1150° C(2100° F)dissolution point in conformity with API Std. Specifications.

Bolting

The body-bonnet bolts are manufactured in accordance with API Std. 600 specifications. The nuts also strictly conform with ANSI B1.1 The stud-bolt nuts. Hexagonal, rigid and hot-forged, bear material notation as well as do the bolt nuts made according to ANSI B18.2.2

Bonnet

The bonnet is integral or separate with the yoke and is the same material as the body. The body-bonnet flange drilling is spot-faced to exactly meet stud bolt nuts. The back seat bushing in the bonnet guarantees that the packing can be replaced even when the valve is fully opened. The stem packing dimensions of the stuffing box are in accordance with API Std. Specifications.

Stem

The heat-treated stems of one-piece construction insure adequate mechanical properties and surface hardness. Friction at the time of opening and shutting is reduced to a minimum friction to accurate machining and lapping.

The round finished surface of the stem head helps to achieve point contact with the inside of the disc housing to eliminate friction.

Disc

The disc of our globe valves is a loose disc and can freely revolve around the stem. This prevents friction and galling with the seating surface when the valve is shut. The disc is furnished with a conical seating surface that has been ground and lapped to a mirror finish. It is of one-piece construction, and forged and heat-treated to deliver the required mechanical properties and hardness.

Body

The cast steel body is designed to insure a wall thickness which is greater at any point than the minimum specified by API Std. 600. Port and seat passage dimensions contorm to ANSI B16.5 Pipe Fitting. The screw-in type seat ring is standard to allow interchangeadility. The standard boyd-bonnet joint is mate-femate. And the flange is round for all valves, Accurate machining insures perfect ccaxiafity of the valve ends and seat ring in addition to exact perpendicularity of the body-bonnet flanges.

Design

JINGJIA cast steel globe valve are designed and manufactured to provide maximum service life and dependability. All globe valves are full ported and meet the design requirements of American Petroleum Institute Standard API 600 & API 6D, BS EN 13709 and generally conform to American Society complete range of body/bonnet materials and trims.

Rang of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steels, For special apolications they can be supplied in other grades of alloy and stainless steell, There's'a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions.

Available Modifications for JINGJIA Cast Steel Valves

Trim Changes

End Connection Modifications

Packing and Gasket Changes

Operator Mounting

Handwheel Extensions.

Pressure EqualizingBy-pass

Customer Specified Coatings

Weld End Bore Changes

Oxygen & Chlorine Cleaning & Packaging.

Applicable Standards

Steel Globe Valves, BS EN 13709/API 600, JIS

Steel Valves, ASME B16.34

Face To Face, ASME B16.10, JIS

End Flanges, ASME B16.5, JIS

Buttwelding Ends, ASME B16.25

Inspection And Test, API 598.

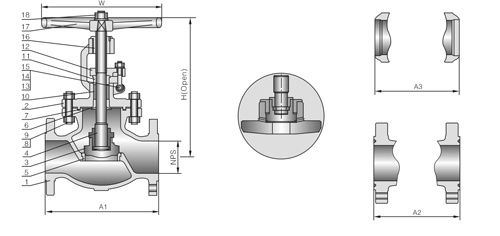

Design Description

Straight Pattern Body Design

OS & Y, Outside Screw And Yoke

BB, Bolted Bonnet

Yoke Integral With Bonnet

Rising Stem And Handwheel

Loose Disc, Choice Of Plug Or Ball

Renewable Seat Ring

Impact Handwheel For 10" & Above

Horizontal Service

Flanged Or Buttwelding Ends

Available With BG Operator.

|

NO. |

Part Name |

ASTM Material |

|

Carbon steel |

1.25Cr-0.5Mo |

2.25Cr-1Mo |

304 Type |

316 Type |

304L Type |

316L Type |

20 Alloy |

|

1 |

Body |

A216 WCB |

A217 WC6 |

A217 WC9 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

A351 CN7M |

|

2 |

Bonnet |

A216 WCB |

A217 WC6 |

A217 WC9 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

A351 CN7M |

|

3 |

Disc |

WCB+13Cr *1 |

A217 WC6+HF |

A217 WC9+HF |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

A351 CN7M |

|

4 |

Stem |

A182 F6a |

A182 F11 |

A182 F22 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

20-Alloy |

|

5 |

Seat Ring |

A105+13Cr *1 |

A182 F11+HF |

A182 F22+HF |

NA |

NA |

|

6 |

Back Seat |

A276 410 |

A276 410 |

A276 410 |

NA |

NA |

|

7A |

Bonnet Gasket |

304+graphite |

304+graphite |

304+graphite |

304+graphite |

316+graphite |

304L+graphite |

316L+graphite |

316+graphite |

|

7B |

Ring Gasket |

Soft steel |

A182 F304 |

A182 F304 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

20/Alloy |

|

8 |

Bonnet Bolt |

A193 B7 |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

A193 B8 |

A193 B8M |

A193 B8M |

|

9 |

Bonnet Nut |

A194 2H |

A194 7 |

A194 7 |

A194 8 |

A194 8M |

A194 8 |

A194 8M |

A194 8M |

|

10 |

Packing |

Graphite |

Graphite |

Graphite |

Graphite *2 |

Graphite *2 |

Graphite *2 |

Graphite *2 |

Graphite *2 |

|

11 |

Gland |

A276 410 |

A276 410 |

A276 410 |

A276 304 |

A276 316 |

A276 304L |

A276 316L |

20/Alloy |

|

12 |

Gland Flange |

A216 WCB |

|

|

A351 CF8 |

A351 CF8 |

A351 CF8 |

A351 CF8 |

A351 CF8 |

|

13 |

Eyebolt |

Carbon steel |

A193 B7 |

A193 B7 |

A193 B8 |

A193 B8 |

A193 B8 |

A193 B8 |

A193 B8 |

|

14 |

Eyebolt Nut |

Carbon steel |

A194 2H |

A194 2H |

A194 8 |

A194 8 |

A194 8 |

A194 8 |

A194 8 |

|

15 |

Eyebolt Pin |

A276 410 |

A276 410 |

A276 410 |

A276 304 |

A276 304 |

A276 304 |

A276 304 |

A276 304 |

|

16 |

Yoke Sleeve |

Bronze |

Bronze *3 |

Bronze *3 |

Bronze |

Bronze |

|

17 |

Hand Wheel |

Malleable iron |

Malleable iron |

Malleable iron |

|

18 |

Wheel Nut |

Carbon steel |

Stainless steel |

Stainless steel |

|

*1 |

PN≥600 CLASS seal face will be HF |

|

*2 |

PTFE Optional |

|

*3 |

Ductile Ni-Resist iron Optional |

|

NA |

tegral with vessell |

We are a grouplized manufacturer of valves and its related supplies, established since year 1984, having 5 manufacturing bases and two trading companies under control, with registered capital of USD 13 million, facility covers 45, 000 Square meters, 500+ staffs and 80+ professionals, we proudly introduce us as a core valve manufacturer in China.