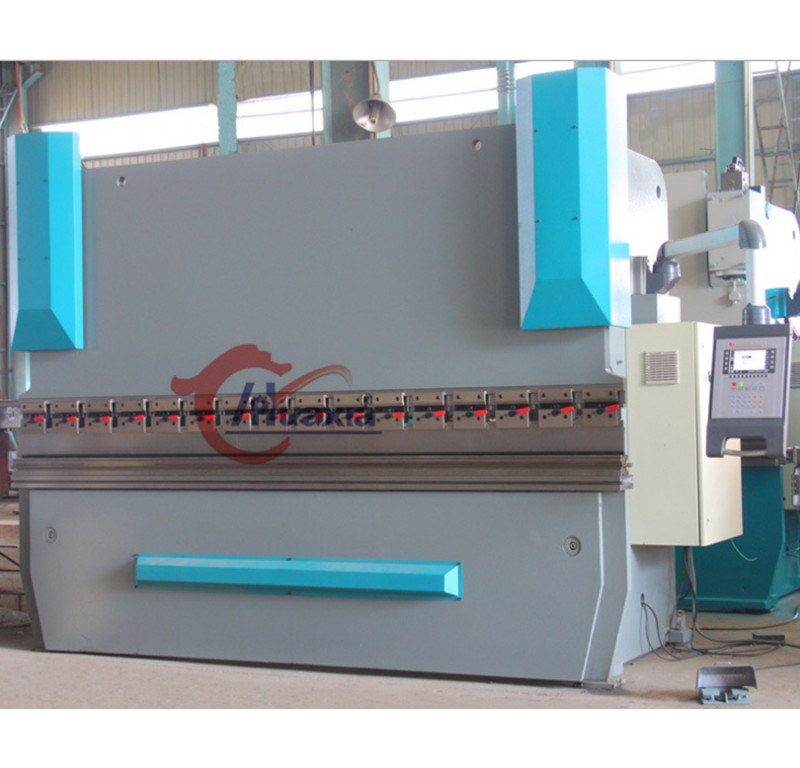

A. Product Information

This series CNC hydraulic press brake, through the servo proportional valve to drive cylinder elongation and returns, so the slider become to rise and fall. Slider synchronization using full closed-loop electro-hydraulic servo control technology, the slider position feedback signal by the grating ruler on both sides to the numerical control system, and is controlled by CNC system synchronization valve opening size, automatically adjust the volume of oil cylinder oil, so that can control the slider (Y1, Y2) axis synchronous operation, keep parallel state of the workbench.

B. The Characteristics of machine:

1. Oveall processed structure, and ANSYS finlte element analysis software is applied to main pares of the machine, which can enssure the reliability of machine tool and the precision of machine

2. Optional CNC controllers, which have the high precision

3. Overload and overflow protection in hydraulic system, essure no leakage

4. Manual oil pump, and oil level can be seen directly

5. All seals in cylinder is imported, high quality and high performance

6. Hydraulic accumulator make the machine run smooth and low noise

7. Double hydraulic oil cylinder provide with mechanical limited stopper and synchronous bar, ensure the reliable operation and high precision

8. Protective fence and safety interlock to ensure the operation safety

9. Emergency stops and foot switch on the machine for the safety

10. Deflection compensation device is fitted

C. Control system

This Machine's numerical control system adopt special system for electrohydraulic servo bending machines of Italian ESA, Netherland DELEM, or Switzerland CYBELEC Company, able to achieve the functions of graphic programming for bending angle, compensation for angle amendment, automatic calculation and adjustment of bending pressure, automatic calculation of compensation for workbench distortion, extending length of workpiece, bending pressure for sole pressing, open distance, and automatic retreat of back gauge, etc.

D. Packaging & Delivery

Packing Detail: Standard exporting package for hydraulic press brake

1, inner machine, it is packaged in moistureproof film.

2, pallet or wood box.

3, ground fixed bolt to confirm steady and avoid destory.

4, tightly exporting standard belf to fasten machine in container.

Shipping Detail: Within 25 days after receive deposit

E. Service

Our machine is simple, generally, you can understand how to operate easily, and welcome to our factory to learn how to operate our machine, we will give good training. If necessary, our engineer can go to your factory, and adjust machine, give good training

If any, pls contact us freely.

If any requirement, pls contact. We will give you acceptable price.

Contact information:

Tel: +86 13721226930

|

|

(kN) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(kW) |

|

|

×(mm) |

×(mm/s) |

|

|

63T/2500 |

630 |

2500 |

1900 |

350 |

150 |

800 |

380 |

5.5 |

2 |

3+1 |

500 |

100 |

3100×1450×2050 |

|

80T/3200 |

800 |

3200 |

2700 |

350 |

150 |

800 |

380 |

7.5 |

3 |

3+1 |

500 |

100 |

3500×1550×2100 |

|

100T/3200 |

1000 |

3200 |

2700 |

400 |

200 |

800 |

420 |

7.5 |

3 |

3+1 |

500 |

100 |

3500×1580×2400 |

|

160T/3200 |

1600 |

3200 |

2700 |

400 |

200 |

800 |

420 |

11 |

3 |

3+1 |

500 |

100 |

3500×1650×2500 |

|

200T/3200 |

2000 |

3200 |

2700 |

400 |

200 |

800 |

420 |

15 |

3 |

3+1 |

500 |

100 |

3500×1680×2550 |

|

250T/3200 |

2500 |

3200 |

2700 |

400 |

200 |

800 |

420 |

15 |

3 |

3+1 |

500 |

100 |

3500×1700×2600 |

|

320T/3200 |

3200 |

3200 |

2700 |

400 |

200 |

800 |

420 |

18.5 |

3 |

3+1 |

500 |

100 |

3500×1800×2730 |

|

400T/4000 |

4000 |

4000 |

3200 |

400 |

200 |

800 |

420 |

22 |

4 |

3+1 |

500 |

100 |

4300×2080×2730 |

|

500T/5000 |

5000 |

5000 |

3900 |

500 |

300 |

800 |

600 |

37 |

5 |

3+1 |

500 |

100 |

5400×2525×4600 |

|

500T/6000 |

5000 |

6000 |

4900 |

500 |

300 |

800 |

600 |

37 |

6 |

3+1 |

500 |

100 |

6500×2525×4200 |

|

500T/7000 |

5000 |

7000 |

5900 |

500 |

300 |

800 |

600 |

37 |

6 |

3+1 |

500 |

100 |

7500×2525×4900 |

|

600T/5000 |

6000 |

5000 |

3900 |

500 |

300 |

800 |

600 |

45 |

5 |

3+1 |

500 |

100 |

5500×2450×4500 |

|

600T/6000 |

6000 |

6000 |

4900 |

500 |

300 |

800 |

600 |

45 |

6 |

3+1 |

500 |

100 |

6500×2450×5100 |

|

600T/7000 |

6000 |

7000 |

5900 |

500 |

300 |

800 |

600 |

45 |

7 |

3+1 |

500 |

100 |

7500×2450×5200 |

|

800T/6000 |

8000 |

6000 |

4900 |

600 |

400 |

800 |

400 |

800 |

75 |

3 |

800 |

100 |

6500×2750×5300 |

|

800T/7000 |

8000 |

7000 |

5900 |

600 |

400 |

800 |

400 |

800 |

75 |

3 |

800 |

100 |

7500×2750×5500 |

|

800T/8000 |

8000 |

8000 |

5900 |

600 |

400 |

800 |

400 |

800 |

75 |

3 |

8000 |

100 |

8500×2750×5900 |

|

1000T/6000 |

10000 |

6000 |

5900 |

600 |

400 |

800 |

500 |

800 |

90 |

3 |

800 |

100 |

6500×2800×5600 |

|

1000T/7000 |

10000 |

7000 |

5900 |

600 |

400 |

800 |

500 |

800 |

90 |

3 |

800 |

100 |

7500×2800×5800 |

|

1000T/8000 |

10000 |

8000 |

6900 |

600 |

400 |

800 |

500 |

800 |

90 |

3 |

800 |

100 |

8500×2800×6100 |

|

1200T/6000 |

12000 |

6000 |

4900 |

600 |

400 |

800 |

500 |

800 |

90 |

3 |

800 |

100 |

6500×3100×5850 |

|

1200T/7000 |

12000 |

7000 |

5900 |

600 |

400 |

800 |

500 |

800 |

90 |

3 |

800 |

100 |

7500×3100×6550 |

|

1200T/8000 |

12000 |

8000 |

6900 |

600 |

400 |

800 |

500 |

800 |

90 |

3 |

800 |

100 |

8500×3100×7150 |

|

1600T/6000 |

16000 |

6000 |

4900 |

500 |

300 |

800 |

600 |

700 |

110 |

3 |

800 |

100 |

6500×3300×6500 |

|

1600T/7000 |

16000 |

7000 |

5900 |

500 |

300 |

800 |

600 |

700 |

110 |

3 |

800 |

100 |

7500×3300×7000 |

|

1600T/8000 |

16000 |

8000 |

6900 |

500 |

300 |

800 |

600 |

700 |

110 |

3 |

800 |

100 |

8500×3300×8000 |

We specialized with plate rolling machine, guillotine shearing machine and other related products. We understand our customers, we care about the future of our business. We want to ensure that you get our good service, not only high quality and speedy delivery.

Press brake, shearing machine, rolling machine, press brake tools.