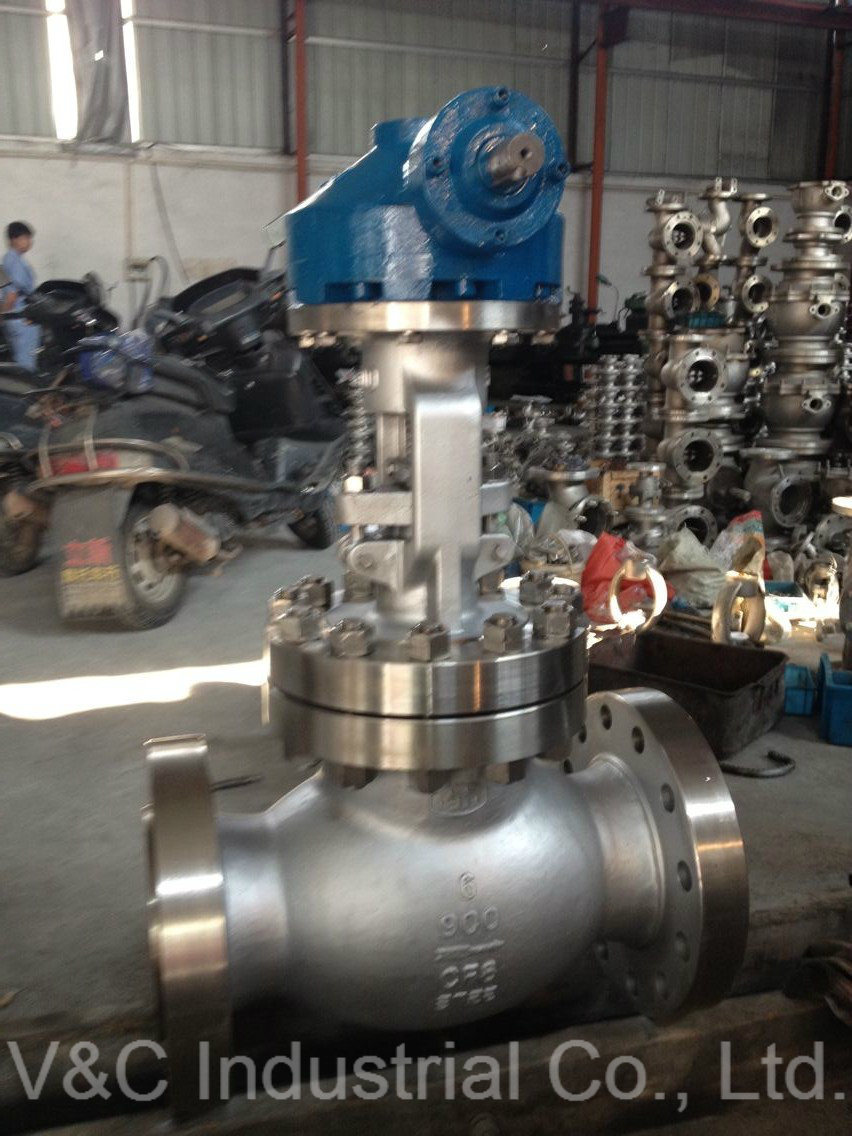

Metal Seated Ball Valve

Compared with soft seal ball valves, V&C metal seated (metal-to-metal) ball valves

have wider working temperature and medium range. During working condition, it has

the features of reliable and safe sealing performance, long service life, easy operation

and less pressure loss. It's mainly used in service of high temperature, high pressure,

severe corrosion and solid material containing services, such as coal chemical, poly

silicon and vitriol/ nitric acid industry.

High Temperature Service

General soft seat ball valve working temperature is limited up to 400° F(210°C), but metal-seat ball valves are guaranteed for a maximum service temperature of 800° F(425°C).

Low Pressure Reliable Sealing

Metal-seat ball valves adopt seat spring structure, which can push upstream seat tightly against the ball surface creating a reliable sealing even if extremely low pressure

Pressure Test

Metal-seat ball valves maximum allowable seat

Leakage: API 598 max 3ml/min/in will be accepted.

Air: ANSI/FC 170-2 CLASS V

Design Features:

1 Our company adopts different valve designs in accordance with different working conditions:

The valve seat and ball sealing surface adopt the metal to metal seal while its ball and seat adopt the special hardening treatment to ensure reliable seal, resistance to high temperature, abrasion and corrosion and a long service life. Its ball and seat are provided with good cutting and self-cleaning functions, applicable for the control over media containing grains and fibers.

2 The seat adopts the plate or compression spring load so that it can avoid the jamming between its ball and seat caused by thermal expansion and cold shrinkage, especially in a state or high or low temperature, in which the flexible seat structure with the automatic compensation function is adopted so that the amount of deformation of its ball and seat can be absorbed by the plate or compression spring, thus it can be opened or closed freely in that state with the reliable seal.

3 Its seat seal can adopt the O-ring, graphite gasket or pretightening graphite seal in accordance with working conditions and temperature; These structure types can be adopted reasonably in accordance with actual working conditions to get a satisfactory result. Our hard sealing fixed ball valve adopts the pre-ball seal structure generally with double block and bleed functions (DBB structure). Generally the floating ball valve adopts the post-ball seat seal structure, which is a kind of one-way seal structure; The floating double-way seal structure can also be adopted in case of special requirements by users.

4 The stem seal of hard sealing ball valve adopts the flexible graphite packing while the flange adopts the flexible graphite with stainless steel wire or the metal twisted graphite gasket, thus boasting the functions of intrinsic safety for fire (conforming to AP1607) and electrostatic prevention (conforming to API607). It adopts the bottom-mounting and blowout-proof structure so as to avoid the blowout of stem caused by the valve misoperation.

Product Range:

| Type | Floating and trunnion mounted ball valve |

| Size | 1/2~42" (DN15~DN1050) |

| Rating | 150~300LB (PN16~25) |

| Temperature Range | <825 degree |

| Body Materials | Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel,SS904L,etc |

| Trim | Tungsten carbide, Stellite,Ni60 coated |

Please visit our website www.vcvalve.com for more information. If any product meet your demand, please contact me directly in detail.

Hope to establish cooperative relationship with your esteemed company!

Tel:86-21-5096 0696

Fax:86-21-5096 0696

Website:www.vcvalve.com

V&C is a leading valve manufacturer in China with over two decades' experience in the design and supply of industrial valves and pipe fittings.

V&C valve manufacturer provide high-quality products and excellent services to Oil & Gas, Petrochemical, Chemical, Energy & Power, Marine and Mining industries from general to severe in application.

Our product range includes Ball Valves, Control Valves, Choke Valves, Gate, Globe & Check Valves, Safety Relief Valves, Automatic Recirculation Valves, Other Industrial Valves, Wellhead Equipment, Pipe and Fittings.

V&C's diversified flow control solution consists of quarter-turn and multi-turn valves in a variety of steel materials, trims, configurations, sizes, pressure classes, which are designed and tailor-made to meet your specified process requirements.

V&C Valves are licensed and certified to API 6D, API 6A, API 600, API 607/API 6FA, ISO 9001 and other monograms or approvals, such as CE, BV, DNV, TUV, SGS, PED and ATEX.

V&C focus on safety and delivery time from valve sizing, engineering, fabrication, test & inspection, painting and shipping. Our philosophy of "High Sense of Responsibility for Clients" ensures our reliability and customers' total satisfaction. V&C is dedicated to continually offering good products and services all at competitive prices worldwide.