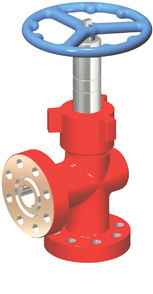

6A Valves including gate valve, plug valve, ball valve, multiple valve, actuated shutoff and check valves may be used for well control, flowline control, re-pressuring and cycling service. It may be operated with a handwheel or a wrench- (or bar-) operated mechanism or with a handwheel-actuated gear mechanism or with a hydraulic, pneumatic and electric-powered actuator.

Multiple valves are full-bore, gate or plug valves, a composite arrangement of valves. They are used in dual, triple, quadruple and quintuple parallel-string completions for production well control, re-pressuring and cycling service. Multiple valves have the conduits of the several bores terminating in, and integral with or permanently attached to, single connectors at each end. The end-connector size is determined by the nominal size of the tubing head or tubing-head adapter to which the lowermost tree valve is being attached.

Actuated valves are provided with an actuator to automatically open or close the valve. They can be flanged, threaded, or other end-connected, full-bore or reduced-opening, gate valves or plug type valves. The actuators may be Hydraulic, pneumatic and electric-powered actuators. The upper limit of the rated temperature range for hydraulic and pneumatic actuators is at least 65° C (150° F). The upper limit of the rated temperature range for retained fluid-powered actuators is at least the upper-limit temperature rating of the mating equipment. Each actuator is subjected to a functional test to demonstrate proper assembly and operation. Valves prepared for actuators, including multiple, prepared for actuators include all parts required to properly function when assembled with the actuator.

Check valves are of the swing and lift check types. The valves may be full-opening or reduced-opening and are used to permit fluid flow in only one direction. All full-opening valves have round passageways through the body and seats. Regular-lift and swing check valves are customarily made with reduced bores through the seat and are sized at the option of the manufacturer.

Positive and adjustable chokes are chokes that include restrictions or orifices to control the flow rate of fluids. Chokes are not intended to be used as shutoff valves. Adjustable chokes have an externally controlled variable-area orifice coupled with an orifice-area-indicating mechanism. Adjustable chokes may be operated by manual or actuator. Adjustable chokes are equipped with a visible orifice-area-indicating mechanism to define the orifice area at any adjusted choke setting throughout its operating range. Positive chokes accommodate replaceable parts having fixed orifice dimensions, which are commonly called flow beans. Special corrosion- and abrasion-resistant materials, coatings or overlays shall be used for adjustable-choke stem tips and positive-choke flow beans

|

Sizes |

1-13/16" ~11" (46~279mm) |

|

Pressure Rating |

2, 000~20, 000 Psi(14~140MPa) |

|

Temperature Rating |

-60~+121º C(KU) |

|

PSL |

PSL1~4 |

|

PR |

PR1~2 |

|

Material |

AA~HH |

|

|

|

Shanghai WIN Mechanical Technology Co., Ltd (hereinafter abbreviated as WINMT) was founded in 2010. It is an international Petroleum, Petrochemical and Natural Gas Industry equipment company specializing in export of Wellhead & Christmas Tree Equipment, 6A Valves, Choke & Kill Manifold Assemblies and Systems, Drill-through Equipment (RAM BOP and Annular BOP), BOP Control Systems (Control Systems for Drilling Well Control Equipment and Control Systems for Diverter Equipment), Kelly Valves, Pump for Pressure Testing, Drilling Choke Controls, General Industry Valves (6D Valves & Globe/Butterfly Valves), Spare Parts, and Forging Products.

WINMT has been striving to become a well-known international supplier of Petroleum, Petrochemical and Natural Gas Industry equipment, and had been committing to provide wonderful products and services for global manufacturers, service providers, purchaser and users. WINMT has established and been operating an excellent and advanced Marketing Mode to ensure that we can purchase wonderful Raw Material and Equipment at competitive prices so that we can reduce overseas customers' Purchasing Costs.

We have been operating a QMS in accordance with ISO 9001: 2008, ISO/TS 29001: 2010 & API Spec Q1 8th Edition, which was accepted by 3rd Party Agency.

WINMT in China

We have a large sales network to promote foreign-made equipment to enter China's market successfully. We also have a set of perfect Supply Chain management system and Procedures to ensure that the overseas purchasers and users can effectively manage Chinese suppliers and manufacturers through WINMT.

WINMT in Overseas Markets

WINMT has a large number of overseas purchasers and customers in Petroleum, Petrochemical and Natural Gas Industry so that we can provide domestic suppliers and manufacturers with overseas sales channels and information.

WINMT's Advantages

WINMT has established and operated a set of perfect Supply Chain management system and Procedures to Select, Evaluate and Re-evaluate the Raw Material Suppliers and Equipment Manufactures in accordance with the Criteria based on the Product Specifications and Industry Requirements.

WINMT has established good and close relationships with Raw Materials Suppliers and Equipment Manufacturers in China.

WINMT will place orders to Raw Material Suppliers and Equipment Manufactures along with the detailed product and process control requirements after successful Supplier Evaluation.

WINMT will plan and perform the effective Supervision to the Material Suppliers and Equipment Manufacture to ensure that the products can meet the specified purchase requirements and can be delivered in time.

WINMT is inviting overseas purchasers and users to discuss on the cooperation with us.

Future Development

WINMT will establish the Product Facility and then to become a Product Manufacturer and Product & Service Supplier.

WINMT will also become the API Monogram Licensee of 6A/6D/7-1/16A/16C/16D and provide the customers with Super Quality Product and Service.