Pneumatic Knife Type Lug Type Knife Gate Valve

| Price: |

US $ 15-5000/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

10/Piece |

| Pay Type: |

L/C,T/T,Western Union |

1.Main Technical Reference

Nominal DN(mm) | 50-600 |

Nominal Pressure PN(MPa) | 0.6 | 1.0 | 16 |

Nominal Pressure PN(MPa) | Strength Test | 0.9 | 1.5 | 2.4 |

Seal Test | 0.66 | 1.1 | 1.76 |

Material | C | P | R |

Major Parts | Body | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti |

Wedge Disc | WCB | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

Valve Stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12MoTi |

Seal Ring | NBR,PTFE |

Packing | Graphite,PTFE |

Applicable Operating Model | Applicable Medium | Water Steam Oil | Nitrose | Nitrc Acid |

Suitable Temperature | -28 °C -300 °C |

PneumaticActuator | Model | OBD-SC Series |

Air Source Pressure | 0.4-0.7MPa |

Administer Standard | Design &Manufacturer | Face to Face | Flanged Size | Pressure& Temp | Test& Inspection |

GBT12237 | GB12221 | GB9113 | GB9131 | GB13927 |

2. Actuator Technology Parameters

Actuator Model | AT/AW Series Single & Double Acting Pneumatic Actuators |

Air Supply Temperature | 0.4-0.7Mpa |

Air Source Port | G1/4'',G1/8", G3/8" ,G1/2" |

Environmental Temperature | Normal Temperature |

Acting Form | Single-acting Pneumatic Actuator &Double-acting Pneumatic Actuator |

Available Accessories | Positioner Solenoid Valve Air Filtering Pressure Reducer Lock up Valve Limit switch Valve Sensors and Gear Actuator |

3. Main Performance Specification

Nominal Diameter | DN50~600mm |

Nominal Pressure | PN(MPa) | 0.6 | 1.0 | 1.6 |

Test Pressure | Strength Test | 0.9 | 1.5 | 2.4 |

Seal Test | 0.66 | 1.1 | 1.76 |

Low-pressure Gas Seal Test | 0.5~0.7 |

Applicable Medium | Water Steam Oil |

Applicable Temperature | Carbon Steel:-19°C~640°C |

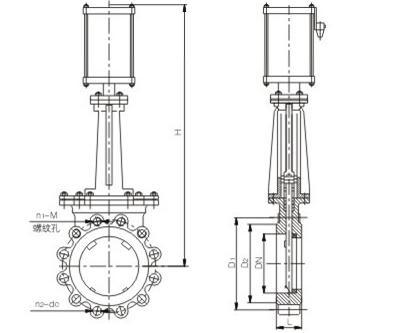

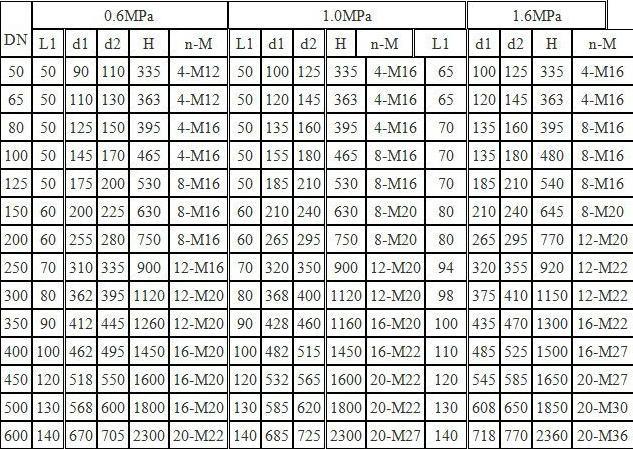

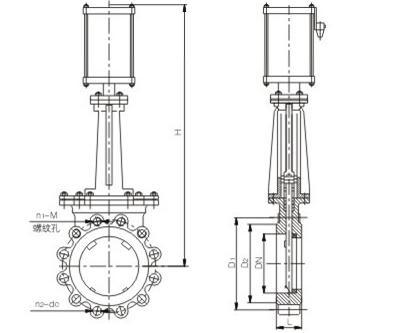

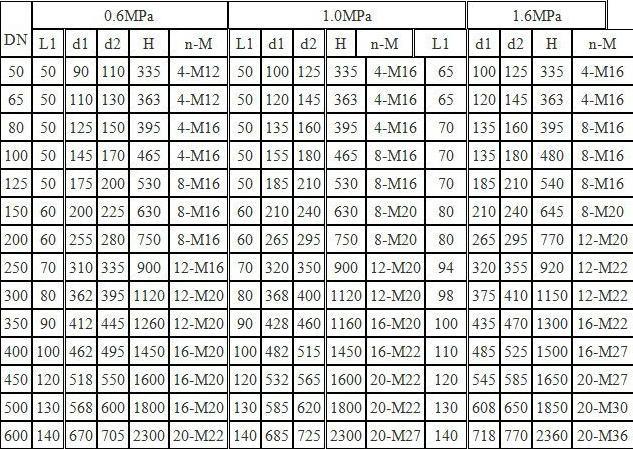

4.Main External and Connection Size

Why choose us:

1. As a direct manufacturer and also a trading company, we are able to have the best resources integrated in China and offer our clients qualified parts at the most competitive price.

2. Quality Assurance: 100% QC inspection before delivery; ISO9001:2008,TS,API and CE certified; Full refund or replacement for quality faulty; One year quality warranty for ALL products.

3. Excellent customer service, responded within 24 hours.

4. Fast delivery: we have large amount of stock ready to ship the next day after order, and for bulk production, we can work on urgent order and deliver in time.

5. We provide OEM service and can make custom parts according to clients'prints or sample pieces.

6. With more than 30 year's manufacturing experience, we've worked with customers worldwide.

7. Monthly production capacity over 2,000pcs, one of the largest in our field in China.

8. Production department prepares products by customers' demands. This is how rigorously we treat all the products delivered to customers, and we consider overwhelming demands for quality our due responsibility towards customers.9. One_Stop service: we can take care of everything from production, shipping, import clearance, door delivery until your order is right there in your hands.

About Us:

ChinaBohai valve group co., LTD was founded in 1980, headquarter was located in TianjinBohai economic zone ,No88,gao ying road,beizhakou town ,jinnan district ,Tianjin of china.And with the land area up to 80000 square meters ,which is a enterprise with product development ,manufacturing and marketing intergrated .Our Workshop:

| Prod Model: |

PZ673X/H/F |

| Size: |

Dn50-Dn2000 |

| Material: |

Stainless Steel |

| Seal Surface: |

Wedge Gate Valve |

| Thread Position Of Valve Rod: |

Outside Gate Valve |

| Application: |

Household Usage |

| Connection Form: |

Lug |

| Pressure: |

Medium Pressure |

Founded in 1980 and headquartered in Bei-Zha-Kou Electronic Industrial Park, Jinnan District, Tianjin, a place incorporated into the prosperous Bohai economic rim, Bohai Valve has been and will continue exploring and innovating. In 2014, Bohai Valve was promoted to a non-area-limited group company in China. The group company is committed to providing stable and reliable fluid control solutions aiming at engineering fields including hydropower, thermal power, steel making, metallurgy, petroleum, chemicals, sewage treatment and water systems.

The group company covers a land of more than 80, 000m2 for its valve manufacturing base and casting factory, and possesses all necessary production and testing means. It is a lare valve manufacturer engaged in valve development, manufacturing, and sales.

Major product lines are manufactured with reference to ANSI, API, DIN, BS, JPI, and JIS standards and China's GB standards by means of the latest technologies favored across the world. They include butterfly valves, gate valves, ball valves, globe valves, check valves, hydraulic control valves, cryogenic valves, throttle valves, metallurgical valves, oxygen tubing valves, and HPHT valves, which are available in more than 100 series and thousands of sizes, with pressure rating ranging from 1.0MPa to 10MPa and port size from DN50 to DN4000. These valves can be operated manually, electrically, pneumatically, hydraulically, and/or electro-hydraulically, and made of different materials, manufactured to different types and sizes, and therefore meet the need for one-stop purchasing.

To ensure the stability and reliability of its quality, the group company uses CNC machine tools, CNC multi-station machining center, extra large processing size (5 meters) vertical lathes and large drilling center for its major machining tasks, maintaining a world automation level throughout its production process. The group company also procures advanced detection equipment and type testing platform for nondestructive testing, spectrum analysis, CMM measuring, supersonic spraying, heat treatment, low leakage test, life test, low temperature performance test, and wear and high temperature resistance test, which not only enhances the machining and testing ability of the factory but also supports the development of new products for harsh industrial environment, thus ensuring the stability of product quality.

The group company also has a large casting base and owns a B3R 125 electric furnace, 3-ton, 5-ton, and 10-ton cupola furnaces, a mobile resin molding line, an epoxy powder spraying line, and a testing center, providing strong and powerful hardware guarantee for the manufacturing of quality valves.

Bohai Valve has long used the advanced management concepts to their factory management and applied the resource management system and warehouse management system to all its products for quality management. It is also one of the first valve manufacturers in China that have passed the ISO 9001, ISO 14001 and OHSAS 18001 certifications. Over the past years, it has been awarded national TS permit and U. S. API certificates for both the company and its products. Bohai Valve now is a member of the supply network for State Grid Corporation's power plants, a member listed in the supply networks of China's other four biggest power companies, a company member of China Engineering Construction Industry Association, and the largest supplier of hydropower valves in China.

We maintain our devotion to innovation and keep learning to gain creative ideas and capabilities, transforming our status from a traditional manufacturer to a tech-based enterprise and developing world advanced valve products. For this purpose, the group company set up the Valve Technology Research Center and pooled together the nation's leading experts and engineers so as to provide the most professional solutions with respect to product development, design, manufacturing and testing.