Case Info:

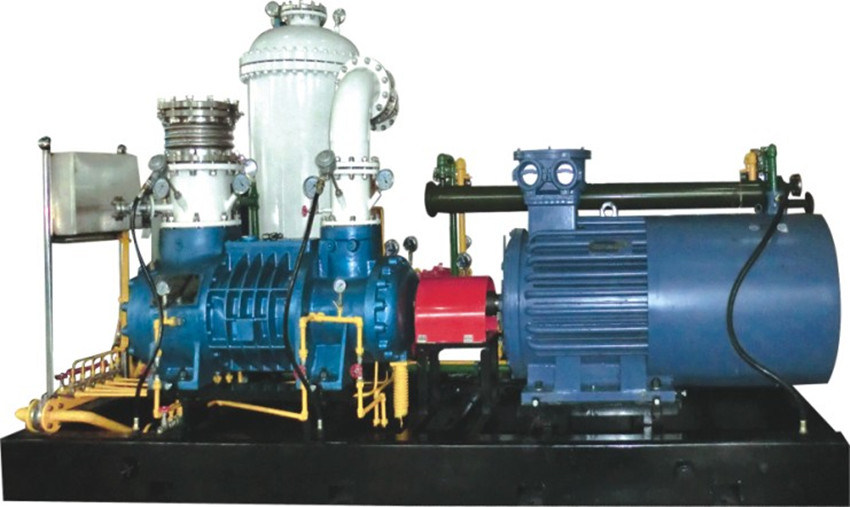

This unit is used in the device of pressure swing adsorption concentration.Applying the principle of PSA can take the concentrate measures to the low concentration oxygen-bearing CBM to make the concentration of oxygen-bearing CBM above 90%.The gas should be pressurized by the screw compressor before entering the device to ensure the gas has sufficient pressure.The usage of the whole device make the full use of the useless resources to save the energy and reduce emission.

Flow of gas-liquid piping system:

The flammable gas comes from the upstream flows into the compressor after purified by scrubber, and then mixed with injected coolant during the compression process, and the gas-liquid mixture will be discharged flows into the separator after compression and cooling. The separated flammable gas enters into downstream piping network as well as separated coolant re-injected into compressor internal, doing the closed circulation in this way.

Process of lubricant piping system:

Lubricating oil in lubrication oil tank pressurized into the main oil pipeline by lubricant pump, passing through the filter and the cooler entering the oil distributor before divided into several ways to the corresponding lubricating points of the compressor. Then flow back to the oil tank through oil return pipe, and the closed circulation is finished.

Advantages of screw compressor set:

1. It's a wet screw compressor, safe and reliable. It's cooled by injected liquid to maintain a lower temperature in the compression chamber.

2. Compressor is acting continuously keeping the discharge pressure stable.

3. It has few wearing parts, reliable operation, long service life and low maintenance cost.

4. High automation, the operators do not need professional training for a long time, and the unit can unattended operating.

5. Low vibration, the compressor can run steadily with high speed, no foundation is realized.

6. Small size, light weight and small occupation area.

7. The effects of the discharge pressure on volumn flow is almost free with the characteristics of gas forced transmission, keeping high efficiency in wide range. In circumstances of no changes of the compressor structure, it is suitable for many working conditions.

8. Baosi water-injected screw compressor is equipped with mechanical seal, to ensure the separation of gas-liquid system and lubricant oil system, so as to avoid the substances in the gas-liquid system entering the bearing lubrication oil system. Make sure the compresor can run reliably.

9. Baosi screw compressor can be equipped with pre- and post processing system, making the operation more stable and make the compressor gas cleaner.

In 2005, the Yi'nuo Baosi Group invested in founding Shanghai Baosi Compressor Co., Ltd. In Shanghai. The company engaged in the famous screw compressor design with manufacturing experts, enjoying the subsidies of the State Council for the first batch of screw studies and design engineers. After 4 years of research and development, we succeedd in mastering the unique BAOSI technology and design for the BAOSI screw rotor, which has independent intellectual property rights.

In May of 2008, the Yi'nuo Baosi Group invested in setting up Ningbo Baosi Energy Equipment Co., Ltd., which formally put the brand into large-scale production, with the steady development of the energy equipment industry and a growing technical team in July of 2009. So far, the company has formed a series of products including screw compressor air end/hosts, medium-pressure screw compressors, screw vacuum pumps, oil-gas multiphase pumps, skid-mounted liquefaction equipment, flammable gases (CBM, oil gas, petrochemical exhaust, biogas, shale gas and other industrial gases), and recycling engineering equipment.

The group now has assets totalling over 500 million RMB, 1800 staffs and 173, 333 m2 factory and office area, as well as more than 50 units of Japanese Mazak machining centers, more than 50 sets of screw rotor machines, 4 sets of German KAPP grinding machines, etc. Annual production reaches 60, 000 units of screw compressor air ends, 5000 sets of screw air compressors, and nearly 200 sets of industrial gas compressors. In regard to protection of intellectual property rights, we have applied for 39 domestic and abroad patents, 17 of which has been authorized, including 2 invention patents, 6 appearance design patents, and 9 utility model patents.