Safty valve for shock absorber of high speed railway

Product Description:DELTA is ISO/TS16949/14001 certified manufacturer, and dedicated to R&D and manufacture of Safty valve for shock absorber of high speed railway.

In the future, more and more industries rely on sophisticated equipment and high degree of automation, DELTA dedicates to the field of key parts of precision equipment, precision medical instrument, automobile and aviation, to provide customized machining services. DELTA would like to cooperate with our customers to work out the qualified machining parts according to samples or drawings within shortest lead time, also we will ensure our QCD (quality, cost, delivery) leading advantage in machining industry, in accordance with ISO14000 and the automobile industry ISO/TS16949 quality system certification requirements.

DELTA is in line with customers "Mutual benefit, Common development"

principle, improve overall strength constantly, sustainable development, to satisfy our customers.

Customized Machining Solution:

1. Develop and manufacturing of machinery Key parts.

2. Turning milling complex parts precision manufacturing.

3. Ultra deep and thin hole processing: processing of ultrafine micro, deep or thin hole with diameter over 0.1mm on the metal parts.

4. Tungsten steel (harden alloy) nozzle, nozzle processing: inner hole mirror polishing, below RA0.05.

5. Precision inner, cylindrical grinding: long, ultrafine grinding, size accuracy can reach to 2μ, coaxial jumping within 2μ.

6. Precision inner, outer thread grinding machining, non-standard screw rod and worm and gear CNC whirlwind manufacturing.

7. Precision mirror grinding and polishing.

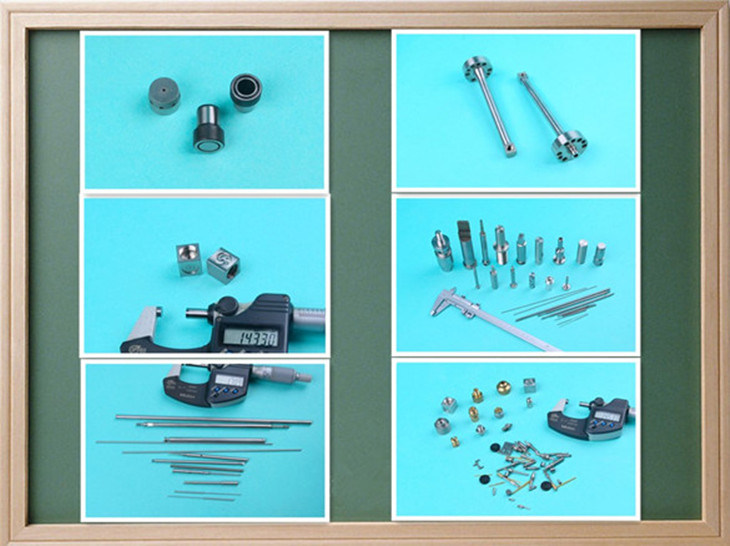

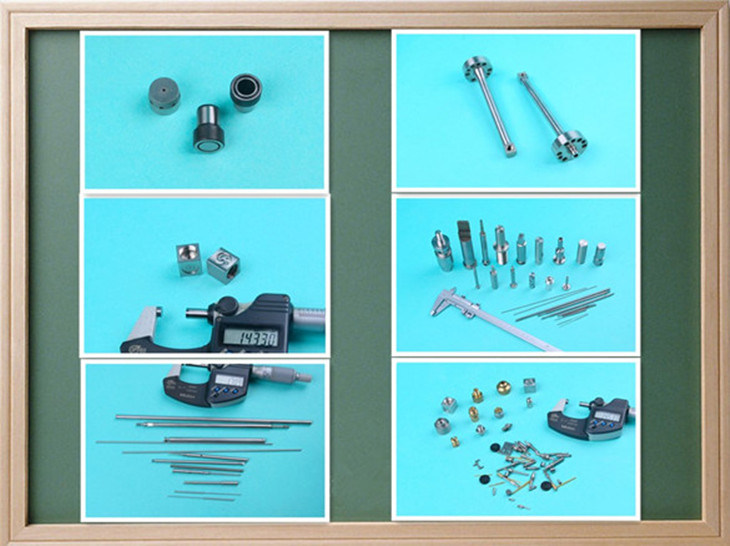

Quality Control:

DELTA manufacturing implement the whole process quality control, and the realization of product traceability, please rest assured.

Lead time and services:

Sample: 20days.

Mass Production: 30days.

Enquiry Response: within 1 working day.

Your purchasing requirement will be fast and fully responded, you will be very comfortable for our service.

Company Pictures:

FAQ:

1. Q: Are you manufacturer or trader?

A: DELTA is a manufacturer with more than 10 years experiences in machining field.

2. Q: What's your location? Which is the nearest port for DELTA?

A: DELTA is located in Taicang city, where is 40minutes away from Shanghai Hongqiao airport. Nearest port is Shanghai seaport and airport

3. Q: What's your MOQ?

A: 1pc if requested.

4. Q: Is it possible to know the status of my order without visiting DELTA?

A: We will offer a detailed production schedule and send weekly report with digital pictures and videos which show the machining progress.

5. Q: What's your payment term?

A: T/T, L/C, Paypal, West Union and etc. We welcome all creditable customers from all over the word.

6. Q: If you make poor quality goods, will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture qualified products until your satisfaction.

Key words:

whirling milling, CNC whirlwind mill, nozzel, medical parts, screw rod, lead screw, Sleeve machining, Feedback rod, Tape hole machining, Kovar tube, Kovar material, Lathing, Precision turning, Precision turned, slim axle, Precision long and thin axis, spindle, shaft, CNC machining, precision milling, CNC, machined, full automation CNC parts, micro hole machining, small hole drilling, EDM hole drilling, Precision thread machining, custom thread rolling, precision customized parts, CNC mechanical machining, aluminum anodized parts, precision machining manufacturer, etc.

| 1. Material: |

| |

| carbon steel, stainless steel, aluminum, brass, bronze, copper, gray cast iron, nodular cast iron, engineering plastic (Delrin, Nylon, Teflon, POM), or according to customer request. |

| |

| 2. Processing machine: |

| |

| CNC machine, grinding machine, full automatic lathe and mill machine, conventional lathe machine, milling machine, EDM drilling machine Thread rolling machine and etc. |

| |

| 3. Finishing: |

| |

| zinc plating, nickel plating, chrome plating, polishing, case hardening, carburization hardening, sand blasting, anodizing. |

| |

| 4. Inspection facility: |

| |

| Image measuring instrument, roughness tester, hardness tester, microscope, thread gauge, digital calipers, micrometer |

| |

| 5. Quality management system: ISO9001: 2008 ISO/TS16949 |

| |

| 6. Min. order quantity: 10pcs (negotiable) |

| |

| 7. Packing and delivery time: |

| |

| Packing: Standard export package, wooden case, carton, wood pallet, or on requirement. |

| Delivery time: 7-30days (negotiable) |

| |

| 8. OEM is welcomed |

| |

| With experienced technical engineers and modern inspecting equipment, our factory can help you to lower cost at the moment of worldwide financial crisis. |

| 30minusts away from Shanghai, we are professional manufacturer specialized in providing precision machining solution with tight tolerance according to your requests and specification drawings. |

| Now 80% of our products are supplied to leader company in various industries, such as high speed rail, filling machine, cleaning machine, medical device and etc. |

| |

| 9. After-sale service |

| |

" Your satisfaction is our goal" is the after-sales service' s purpose of DELTA company. DELTA constantly sum up experiences in the after-sales service, and constantly improve the service quality, and constantly strengthen the work dynamics, gradually form a set of high quality, complete after-sales service system, and solve the customers' worries, improve the credibility of product quality.

|