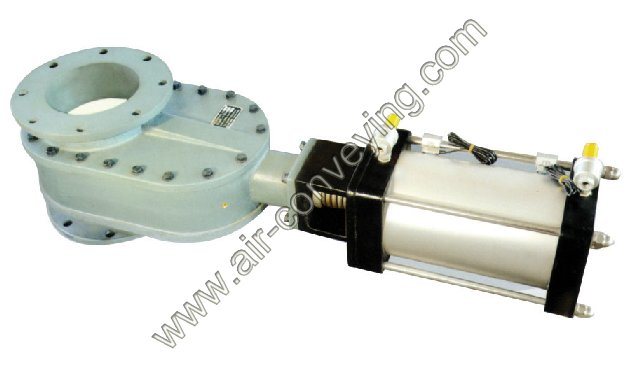

The pneumatic double gate valve can be used as the discharge valve, exhaust valve, and clear valve with pneumatic conveying system. The gate valve has a good sealing performance, high wear resistance and low loading start-up. The material of closed surface between valve plate and cover is thermal spraying, hard and wear-resistant but smooth. The stuffing material is the carbon fiber packing.

We design the pneumatic conveying system and make the conveying components. The pneumatic conveying system are considered, such as the type of material used, conveying distance, system constraints including feeding and discharging, health and safety requirements, and the need for continuous or batch conveying.

Specializes in pneumatic conveying of dry bulk solids materials for the processing industries.

Some common solids as flour, sugar, cement and many more, can be suspended and transported in air - referred as pneumatic conveying. A pneumatic conveying system may transport solids up to approximately 50 mm size. The powder or solid must be dry, with no more than 20% moisture and not sticking.

In a pneumatic conveying system, most of the energy is used for the transport of the air itself. The energy efficiency of a pneumatic conveying plant is therefore relatively low, but this is often outweighed by easy handling and, in well designed systems, dust free solutions.

In general the length of a pneumatic system should not extend 300 m for each pneumatic unit. The products can be conveyed over long distances by connecting the systems in series.

There are three basic designs of pneumatic transport systems:

Dilute phase conveying at a high gas speeds (20 - 30 m/s)

Strand conveying at a limited gas speeds (15 - 20 m/s)

Dense phase conveying at a low gas speeds (5 - 10 m/s)