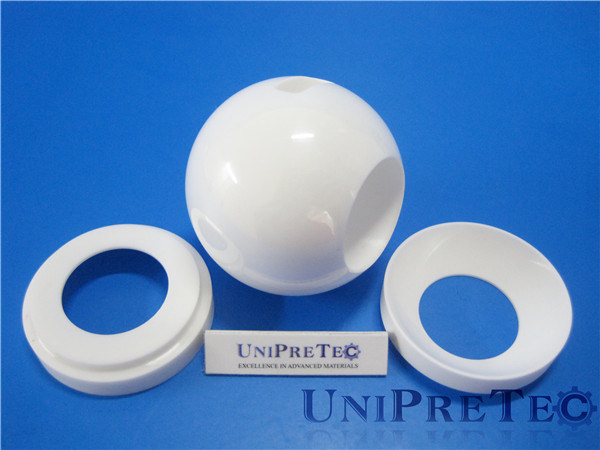

Properties of Zirconia Ceramic Valve

(1). Excellent in electrical insulation;

(2). High hardness and wear/corrosion resistance;

(3). High working temperature;

(4). Good thermal shock resistance;

1. About Zirconia

Unlike traditional ceramics that tend to be hard and brittle, Zirconia has high strength, wear resistance, and flexibility far beyond those of most other technical ceramics. Zirconia is a very strong technical ceramic with excellent properties in hardness and corrosion resistance, all without the typical property of ceramics brittleness. Its unique resistance to crack propagation and high thermal expansion make it an excellent material for joining ceramics with metals like steel. Due to Zirconia's properties it is sometimes referred to as the "Ceramic steel".

2. Zirconia Properties:

- High strength

- High fracture toughness impact resistant

- High hardness

- Wear resistant

- Good frictional behavior

- Electrical insulator

- Low thermal conductivity thermal insulator

- Corrosion resistance in acids and alkalis

- Modulus of elasticity similar to steel

- Coefficient of thermal expansion similar to iron

3. Zirconia Applications

- Wire forming/drawing dies

- Insulating rings in thermal processes

- Precision shafts and axles in high wear environments

- Furnace process tubes

- Wear resistance pads

- Thermocouple protection tubes

- Sandblasting nozzles

- Refractory material

- Extrusion dies

- Bushings and caps

- Kiln furniture crucible

- Fiber optic ferrules and sleeves

- Knives and blades

- Fuel cell parts

- Bearings & rollers

- Welding nozzles & pins

- Laser parts

- Gas igniters

- Electric insulator

- Ceramic guiders

- Oxygen sensors

- Medical and surgical component

- Mechanical seals

- Pumps, pistons, and liners

|

Characteristics |

Unit |

95 Al2O3 |

99 Al2O3 |

ZrO2 |

GPSi3N4 |

BN |

Glass Ceramic |

|

Crystal Structure |

- |

hexagonal |

hexagonal |

tetragonal |

hexagonal |

hexagonal |

- |

|

Color |

- |

white |

ivory |

white |

gray |

white |

white |

|

Density |

g/cm³ |

3.65 |

3.88 |

5.95 |

3.22 |

2.26 |

2.55 |

|

Water Absorption |

% |

0 |

0 |

0 |

0 |

0.0-1.0 |

0 |

|

Young's Modulus |

Gpa |

280 |

350 |

205 |

295 |

670 |

65 |

|

Vickers Hardness |

Gpa |

14 |

20 |

12 |

18-20 |

- |

- |

|

Flexural Strength |

Mpa |

280 |

300 |

900 |

650 |

51 |

100 |

|

Compressive Strength |

Mpa |

2000 |

2500 |

2200 |

2200 |

230 |

500 |

|

Thermal Conductivity |

W/(m•K) |

18-25 |

30 |

2.2 |

25 |

20 |

1.70 |

|

Thermal shock resistance |

ΔT(C°) |

220 |

180-200 |

280-350 |

450-650 |

>1500 |

25-100 |

|

Max. Working Temperature |

C° |

1500 |

1700 |

850 |

1200 |

960 |

800 |

|

Volume Resistivity |

Ω . cm |

>10^15 |

>10^14 |

>10^12 |

>10^14 |

10^13 |

10^16 |

|

Dielectric Constant |

- |

9.50 |

9.80 |

26 |

8.20 |

4.08 |

6.02 |

|

Dielectric Strength |

kV/mm |

16 |

22 |

- |

16 |

375 |

40 |

UNIPRETEC is in providing solutions to difficult problems using the most high-tech advanced ceramics precision components and products. We develop, manufacture and supply precision products which required hard wearing, lightweight, non-contaminating, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties.

With many years of experience in research and development in advanced technical ceramic materials, process development, manufacturing of precision components and small assemblies for the various niche applications for the automotive, aerospace, oil & gas industries, foundries, industrials, food, medical, chemical etc. and also consulting & working with most advanced ceramics manufacturing companies around the world, we are now able to offer following services:

- Design, research & development of materials

- Material processes and manufacturing of precision components & assemblies

- Manufacturer & supplier of quality precision components made from advance technical ceramics with reasonable price and excellent delivery

- Consultation for product development, manufacturing & quality control

- Business development

- Sales & Marketing.

Advance engineering ceramic materials:

- Aluminium Oxide (Al2O3)

- Zirconium Oxide (ZrO2)

- Silicon Carbide (SiC, SiSiC)

- High pressured & Hot pressed sintered Silicon Nitride (GPSN & HPSN)

- Boron Carbide (B4C)

- Aluminium Nitride (AlN)

- Machinable Ceramics (Glass Ceramic & Boron Nitride)

We welcome any opportunity related to above products from any one who are interested in for development or sourcing high tech ceramic components from us. If you need any further information, please do not hesitate to contact us at our office or if you may need my visit for further detail discussion, please do not hesitate to contact me either.