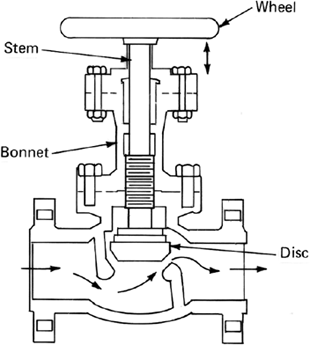

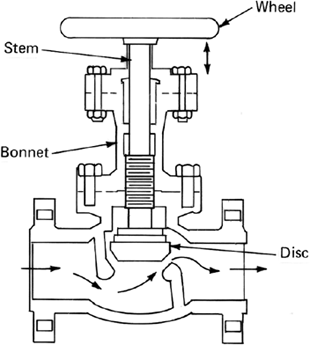

The globe valve is named after its shape. Its body has an interior partition, and the valve inlet and outlet centers are inline. This configuration forces a change in the direction of flow in the form of an S. A Globe valve is a device for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body.

Globe Valves have a spherical body shape with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug can be screwed in to close (or shut) the valve. The plug is also called a disc or disk. In globe valves, the plug is connected to a stem which is operated by screw action in manual valves. Typically, automated valves use sliding stems. Automated globe valves have a smooth stem rather than threaded and are opened and closed by an actuator assembly. When a globe valve is manually operated, the stem is turned by a hand wheel.

Generally speaking, there are 3 styles of globe valves: straight pattern, angle pattern and Y-pattern. These are determined by the geometry of the end connection and the stem. In a straight pattern globe, the end connections for a straight line with the stem pointing vertically from this line. A Y-pattern is similar but the stem is angled by 45 degrees from the inlet-outlet path. An angle valve has the inlet and outlet oriented 90 degrees from each other with the stem perpendicular from one and in line with the other. Typically globe valves are made of metallic alloys, although some synthetic materials are available. These materials are chosen based on pressure, temperature, and controlled media properties. Corrosive and/or erosive process streams may require a compromise in material selection or exotic alloys or body coatings to minimize these material interactions and extend the life of the valve or valve trim components. Typically, carbon steel alloys are specified for no corrosive applications. Other alloys such as Hastelloy, Monel, Inconel and others are available.  Packing material must also be considered during valve selection. Typically the requirement for a low friction packing conflict with a durable material that will provide low maintenance requirements during service life. Corrosive applications can further complicate packing material selection as the typical packing materials may or may not be compatible with the processed materials. Typically graphite or PTFE is used due to its low friction coefficient. Enviro-seal applications also have the availablilty of constant applied force (live-load) packing. While more complex, it allows for constant packing force load throughout the life of the packing material. This packing helps meet contemporary environmental laws. Globe valves have a lot of advantages: they offer precise throttling and control and have high-pressure limits. Conversely, they offer a low coefficient of flow and are not good selections in applications that require cleanliness or sterility.

Packing material must also be considered during valve selection. Typically the requirement for a low friction packing conflict with a durable material that will provide low maintenance requirements during service life. Corrosive applications can further complicate packing material selection as the typical packing materials may or may not be compatible with the processed materials. Typically graphite or PTFE is used due to its low friction coefficient. Enviro-seal applications also have the availablilty of constant applied force (live-load) packing. While more complex, it allows for constant packing force load throughout the life of the packing material. This packing helps meet contemporary environmental laws. Globe valves have a lot of advantages: they offer precise throttling and control and have high-pressure limits. Conversely, they offer a low coefficient of flow and are not good selections in applications that require cleanliness or sterility.

Globe valves may, of course, be used also for on-off duty, provided the flow resistance from the tortuous flow passage of these valves can be accepted. Some globe valves are also designed for low flow resistance for use in on-off duty.

Also, if the valve has to be opened and closed frequently, globe valves are ideally suited because of the short travel of the disc between the open and closed positions, and the inherent robustness of the seating to the opening and closing movements.

Globe valves are also suited for controlling in situations where there are high pressure differences between the inlet and outlet. The winding path that the media has to follow does not let it speed up too much and reduces the impact of the Bernoulli Effect that often damages ball valves.

Globe valves may therefore be used for most duties encountered in fluid handling systems. This wide range of duties has led to the development of numerous variations of globe valves designed to meet a particular duty at the lowest cost.

Packing material must also be considered during valve selection. Typically the requirement for a low friction packing conflict with a durable material that will provide low maintenance requirements during service life. Corrosive applications can further complicate packing material selection as the typical packing materials may or may not be compatible with the processed materials. Typically graphite or PTFE is used due to its low friction coefficient. Enviro-seal applications also have the availablilty of constant applied force (live-load) packing. While more complex, it allows for constant packing force load throughout the life of the packing material. This packing helps meet contemporary environmental laws. Globe valves have a lot of advantages: they offer precise throttling and control and have high-pressure limits. Conversely, they offer a low coefficient of flow and are not good selections in applications that require cleanliness or sterility.

Packing material must also be considered during valve selection. Typically the requirement for a low friction packing conflict with a durable material that will provide low maintenance requirements during service life. Corrosive applications can further complicate packing material selection as the typical packing materials may or may not be compatible with the processed materials. Typically graphite or PTFE is used due to its low friction coefficient. Enviro-seal applications also have the availablilty of constant applied force (live-load) packing. While more complex, it allows for constant packing force load throughout the life of the packing material. This packing helps meet contemporary environmental laws. Globe valves have a lot of advantages: they offer precise throttling and control and have high-pressure limits. Conversely, they offer a low coefficient of flow and are not good selections in applications that require cleanliness or sterility.