The Smart Choice for Cutting Costs in Flue Gas

In China, on the other hand, the companies charged with making FGD a reality attempted to engineer a solution to the problems associated with slurry handling.

Around 1968, installation of FGD systems sharply increased in both the USA and

China, in contrast to the previous decade when FGD installation proceeded slowly

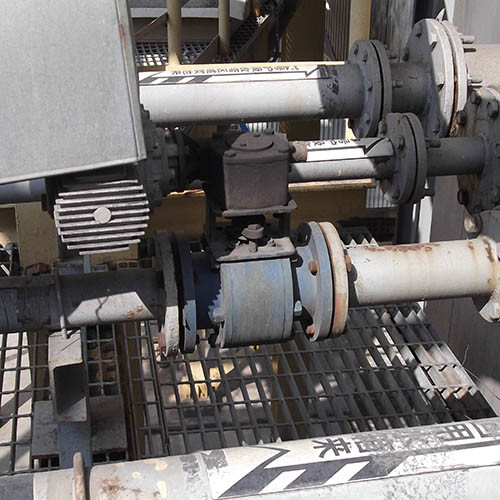

[16]. As demonstrated in figures 6 and 7, ceramic materials have the strength to resist high levels of abrasion whereas stainless steel does not. The development of ceramic valves was one of several technological breakthroughs that helped to make FGD not only feasible but affordable.

3. Ceramic Ball Valves in FGD Systems

3-1 Advantages

3-1-1 Materials

In this paper, we will consider, four different ceramic materials: Alumina (AI203), silicon carbide (SiC), and zirconia (2r02), and silicon nitride (Si3N4). The qualities of the materials allow the valves to be matched to particular applications. Figure 5 shows the performance characteristics of the different ceramic materials.

Performance Characteristics particular applications.

The 99.5% alumina has a high level of abrasion and corrosion resistance, and it remains stable at extremely high temperatures; It is also lower in price than almost al other ceramic materials (see figure 5). As shown in figure 8, the ceramic materials differ somewhat in their performance against the corrosively of certain chemicals at different temperatures.

A much higher grade is 99.9% alumina - one of the purest forms of alumina available. Because of its fine particle size, it has significantly higher corrosion resistance properties than either of the 99.5% alumina ceramics. Valves made of

99.9% alumina can withstand the most severe services yet remain affordable.

Silicon carbide has an extremely high hardness factor; In fact, only diamond and boron carbide are harder. It is 45% harder than our standard alumina (see figure 5). It has the highest corrosion resistance of all fine ceramic materials (see figure 8). It also exhibits high thermal conductivity, high thermal-shock resistance, and strength ' durability at extreme temperatures. On the downside, the high cost of silicon carbide may lead users consider alumina as a suitable alternative.

Zirconia has the highest strength and toughness at room temperature of all engineered ceramics. It has a'~rgh level of resistance to impact and mechanical shock, and cavitation (see figure 5). On the other hand, it is less corrosion resistant and more susceptible to impingement than alumina. Therefore, it is used primarily for high torque or high pressure applications.

FOYO manufactures ball valves, gate valves, globe valves, check valves, strainers, flanges and some other pipe fittings, all of which are devices used for the control of fluids. Moreover we are specialized in ceramic valves, titanium valves, nickel valves and other special material to handle the most abrasive or(and) corrosive applications, including mining, coal fired power plants, steel works, polysilicon, pneumatic conveying, recycling, Oil and Gas, pulp and paper and petro chemistry.

Over the years, FOYO has supplied valves and valve related components to our customers for the most demanding applications. Our professional and skilled engineers, structure and state of the art production facilities allow our highly qualified personnel to manufacture a product in a short period once the material has been chosen.

Foyo supplies a large variety of valves and valve configurations for a wide variety of purposes and conditions: Different uses (on/off, control), different fluids (solid, liquid or gas; Combustible, toxic or corrosive), different materials (metal or nonmetal) and different pressure and temperature conditions (low, medium or high pressure applications and low-, room- or high-temperature applications).

Foyo Valves are strictly designed, manufactured and tested according to API, ANSI, BS, JIS, DIN and some other international standards. And the materials of the valve body include ductile iron, carbon steel, stainless steel, duplex stainless steel, 99% alumina and zirconia ceramics, titanium, nickel and some other materials specified by our customers.

The measure of our success is in the high quality products and service we deliver to our customers. We aim for highly profitable advancements and new heights in both services and technology.

Give us the opportunity to prove that our customers' needs are our top priority. Please send us your requirements and take advantage of our extensive experience and know-how.